Unfortunately my string of bad luck at Drag Week has continued this year, and after the first day I'm out of the competition again. I'm typing this Tuesday morning; Joel and I are in Indianapolis, the Mach 1 is on the trailer, and we are going to go watch the racing at the track today before heading back home. I will type a more complete blog entry later, but basically what put us out were EFI problems. First I had issues with the injectors; the car ran dead lean on its first and only pass, and I still don't know what the issue is; I think it must have to do with either the injectors or the EFI box, but I don't know for sure. Then after the pass, while sitting in the staging lanes, the car developed a bad miss. We eventually figured out that the left bank of coils was just not firing, but ran out of time yesterday to get the problem debugged and fixed. We now know that the left bank coils lost 12V power; there are two relays up under the dash that provide power to each bank of coils, and so either one of the relays went bad, or we lost a wire connection, or something like that.

That's the story in a nutshell; I'll elaborate later. I still have not been able to find a USB cord that fits my camera, so I still can't post my pictures, but I'll be taking more today and will post them later also. In my class, I haven't seen the times but I'm guessing Curt Johnson is the leader; he ran a 9.13 yesterday. No way I was going to be able to match that, so I probably wouldn't have been in a position to win. But it would have been fun to race at least

Updated details and pictures are below:

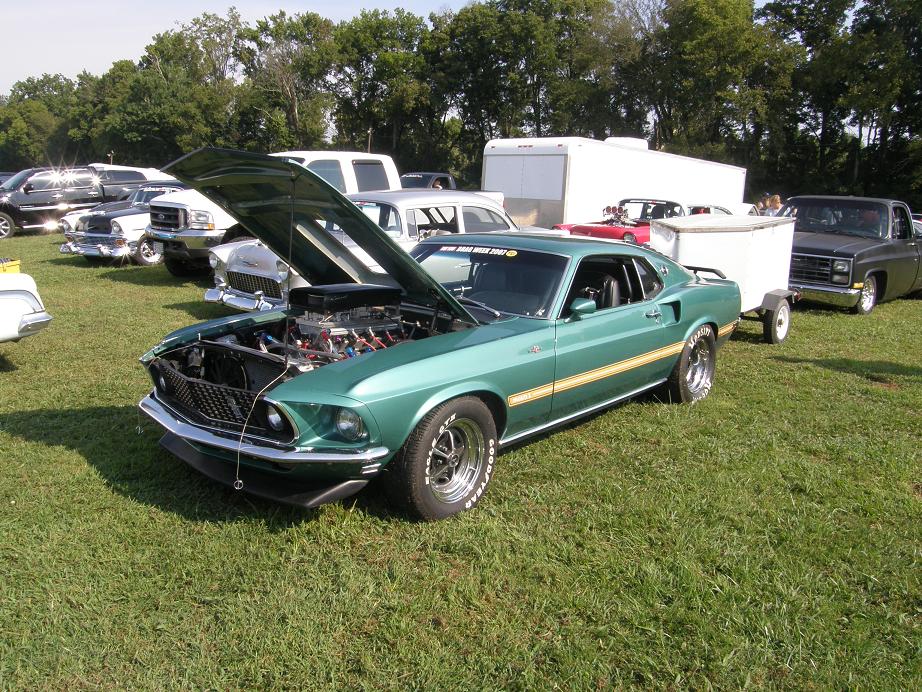

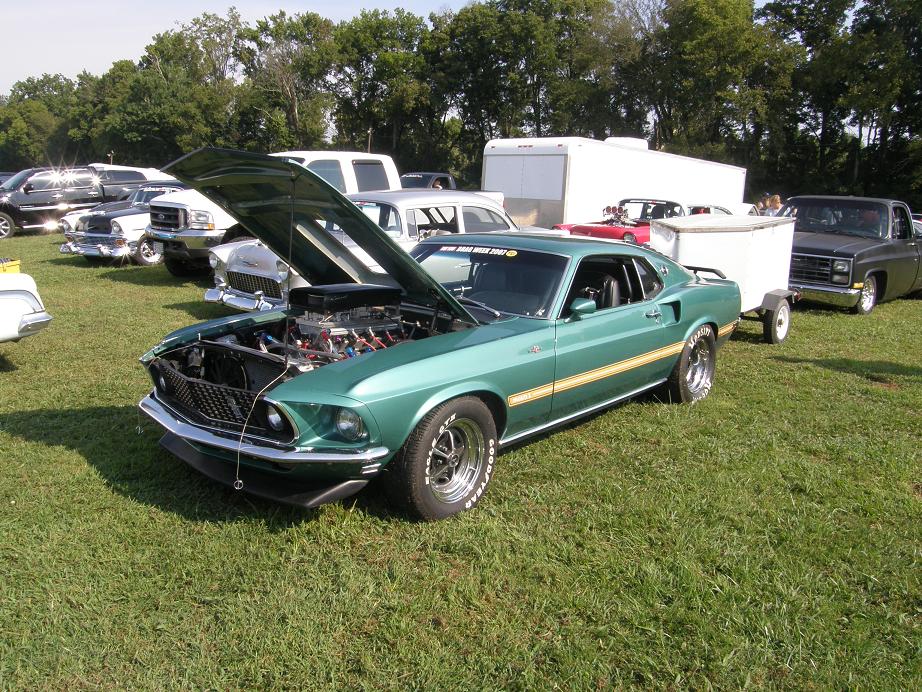

Updated details and pictures are below:Here are some pictures from Sunday, Drag Week registration day. But first, here is a photo of a very close shave we had getting the Mach 1 on the trailer last Friday night. We were loading the car and my little Drag Week trailer together, and the car was 90% up the ramp when the rear wheels spun and it went sideways. I stopped right away, and Joel hooked up the winch and we pulled the car the rest of the way onto the trailer with that, but looking at the picture you can see how close it was to coming off. At least two thirds of the right rear tire was off the ramp when the car stopped; that was a close one:

Here's a pic from Sunday morning, in the hotel parking lot prior to leaving for Beech Bend Raceway:

Once at Beech Bend we parked the truck and trailer and got the car off; here I am backing it off the trailer with Mike Moore and Tom Posthuma spotting:

Once off the trailer I pulled the car into the registration line. It seemed to extend forever. Here's a couple of pictures:

Here's a shot under the hood of the Mach 1 while in the registration line:

Here's some pictures of Jack Miller's Cougars in the registration line. They were beautiful cars, both running in my class at the start of the event anyway. That's Jack at the far left in the first photo, and Eugene in the driver's seat in the second. Eugene was driving the second car:

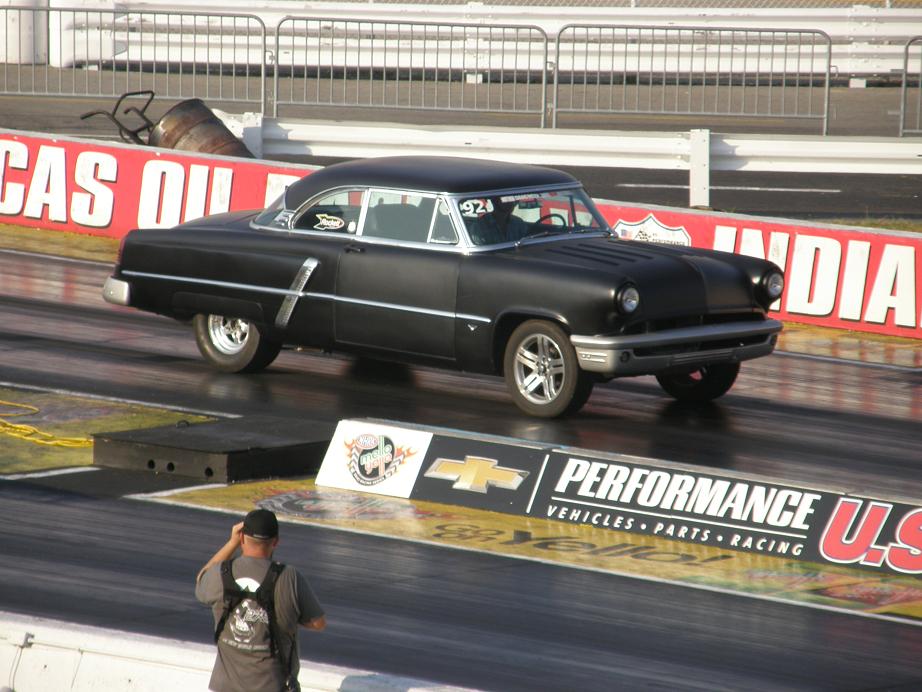

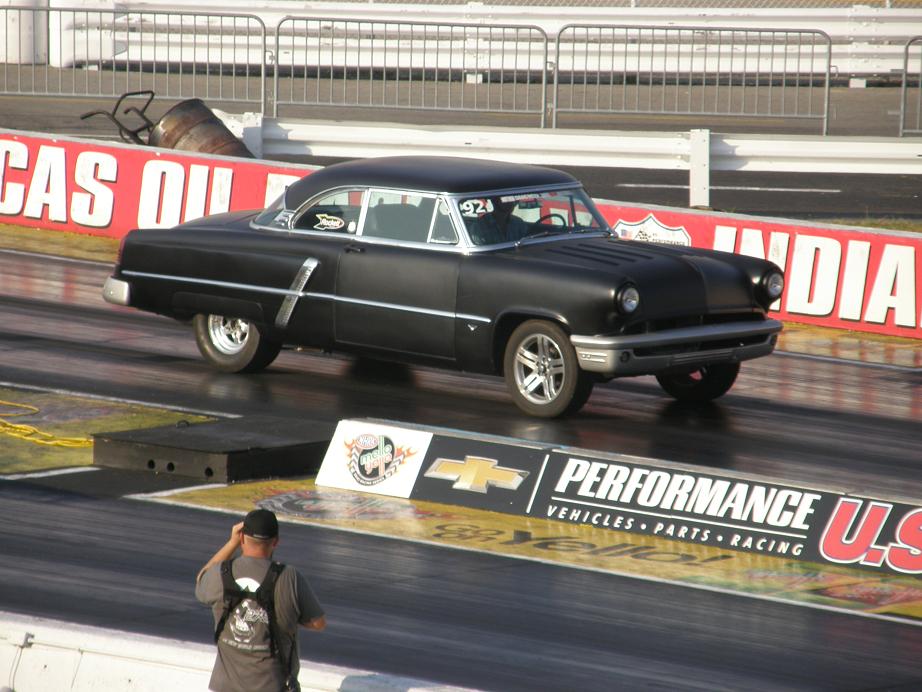

After a few minutes of being in line Larry Warpula and his son Clint pulled in a few cars behind me with their FE powered '53 Lincoln. Really a good looking car, and a very unique Drag Week trailer, too:

As always, there was a wide variety of cars at the track; that's one of the things that makes Drag Week so interesting. This thing deserved a couple of photos just for being weird. It featured five leaf blower in the back of the car, supercharging the engine. I understand that it was some kind of weird TV show project or something. Not really my cup of tea, but interesting nonetheless:

Here's a pic of Mike Crow's Dart. A very nice, clean small block naturally aspirated car. I talked to Mike at Indy on Tuesday and he is running low 10s with the car:

Here's another view down the registration line, as I got closer to the tech inspection tent. I think that's Rick Johnson from Gear Vendors on the far right of the photo:

This blown Mercury Marauder has been at several Drag Week events, and the owner/driver continues to improve on the car as time goes by. I talked to him in the registration line for a while and he is thinking of switching to turbos and doing work on the front suspension. He seems pretty serious about making the car go faster and faster:

After we finally got through the tech line we pulled the car into the shade to do some work. Here's a shot of the engine while the pushrod change was going on:

At the end of the day, when we'd finally made it into the event, we got done with all the work on the car and put it back on the trailer for the trip to the hotel. Here's a shot from up on the trailer; the trunk monkey is doing his thing

Monday morning we arrived at the track at 8:00 and got the car and trailer unloaded. At 8:30 the driver's meeting started,

hosted by David Freiburger from Hot Rod. One of the first orders of business that Freiburger took care of was to place a call

to Larry Larson, winner of the last five Drag Week Unlimited titles. I heard that Larry was unable to come this year

because of customer commitments with his chassis business, so Freiburger called him in front of the whole crowd of drivers,

and we all screamed "HI LARRY" at Freiburger's cell phone. It was pretty funny; everybody likes and respects Larry and its

too bad that he didn't make the race this year, because he would have been in a pretty good race.

Freiburger also announced the class count and total number of cars at the event. It was 230 cars, biggest Drag Week ever.

But, this was still short of the 250 car limit; as expected, there were a bunch of last minute no-shows. So, in addition to the

19 racers who showed up with no reserved spot and got in (including me), there were an additional 20 spots available!

Freiburger introduced the sponsors, who all got a big round of applause. The main sponsor this year was Pep Boys speed

shops; I guess they have 100 stores opened nationwide now. Jack Day from Rockett Brand Racing Fuels was there; Jack has

been a sponsor of every single Drag Week. Also Rick Johnson from Gear Vendors was there, and I think Rick has been a

sponsor of every Drag Week event too. Then Keith Turk came up and went over the rules, and finally

turned us loose to go racing. They were running all the class cars for the first hour and a half, and then the daily driver

cars for the next hour and a half, and then finally an open racing block of time for the last couple hours of the day's

race.

We had pretty much gotten our stuff off the trailer and the trailer parked, but didn't have the car ready to run yet, so

Joel and I worked on that for a half hour or so after the driver's meeting. By the time I got the Mach 1 into the lanes,

a bunch of cars had already run, and there was a long waiting line in the staging lanes. Also it was hot out there, at least

95 degrees, and really humid, so the staging lanes were not a pleasant place to be. Finally after close to an hour I got

within six cars of the front of the line, and put my gear on to get ready to go.

When I got to the next up position, I started the car to warm it up a little and pushed the datalogging button. I had worked

hard over the last few weeks to get the datalogging working in the car. The MS3X EFI system writes the data to a little

SD card that is pushed into the box, and then you pull the card out and plug it into a laptop to read the data. This way

you don't have to have a laptop in the car to log the data. The datalogging LED was blinking so I knew the data was

being recorded. It was really, really hot in the car; I had to buy a new helmet this year to pass tech, and it had a clear

plastic face shield, and I was sweating so much that my glasses kept sliding down my nose, and I had to try to reach up

underneath the helmet to get them on straight again. With the five point harness strapped on, the heavy fireproof racing

jacket and pants, the gloves and neckbrace, and the tight confines with the window net and cage in the Mach 1, it was not

a comfortable place to be. One thing for sure, my Galaxie is a lot more comfortable to race than the Mustang, especially

in this kind of heat.

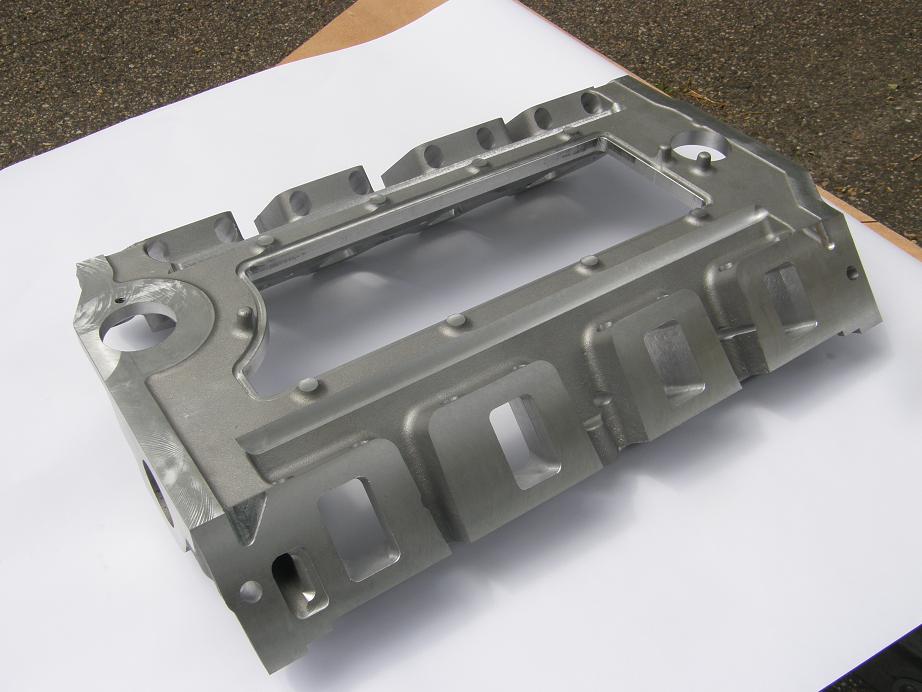

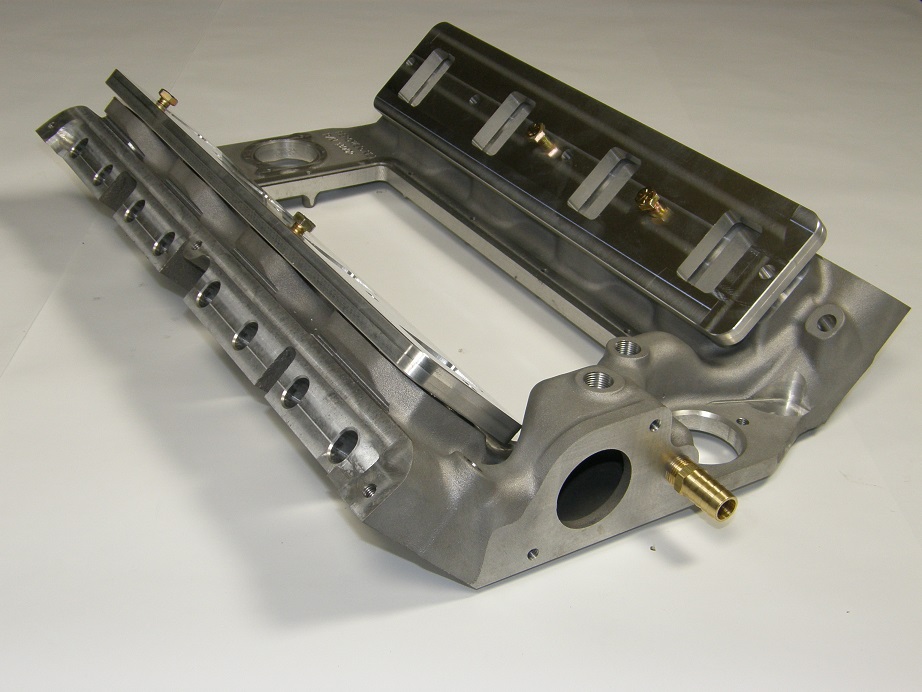

Finally they waved me up the starting line, and I checked to be sure that the datalogging LED was still blinking. My big

concern for this first pass was to get some good A/F data so I could tune the EFI system. Prior to the event I had changed

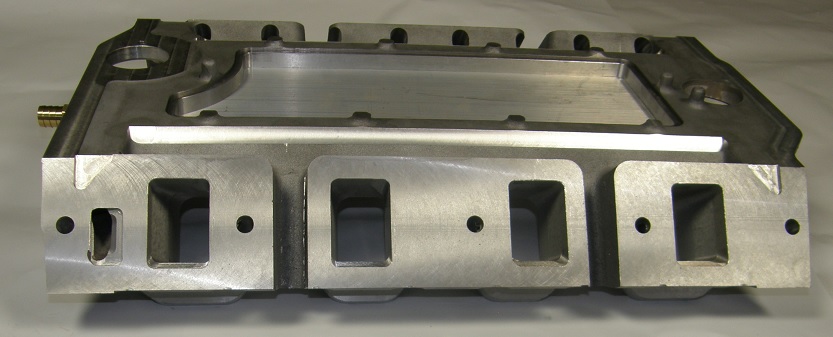

out the fuel injectors for some Injector Dynamics units; these injectors came with individual flow test data, and each one is individually

labeled, so you can use the fuel map tables in the MS3X to tune each injector differently. This way you know that each one

is delivering the same amount of fuel. I thought that might give me a little power edge, so I made the change to the

injectors, but the downside was that the ID (Injector Dynamics) injectors were a higher flow rate than the old injectors. There

is a parameter in the fuel injection system called "Required Fuel" that has to be input depending on the size of the fuel

injectors. There is a calculator in the EFI software that you use to determine the Required Fuel variable, where you input

the size of the engine and the injector's peak flow rate. From the calculator you get the Required Fuel variable and input

it into the sofware. I went through this with the new injectors and stuck the value in the software when I installed the

injectors last week. My EFI guru friend Scott Clark told me that there may be some minor adjustment required to the

Required Fuel variable after this, but nothing major. So I was going to check the datalog after the first pass for A/F

and then make any adjustments to the Required Fuel variable after that.

I watched the pair of cars in front of me go down the track and then got the signal to do the burnout. I pumped up the brakes,

hit the line lock, and spun the tires. Unfortunately, the car went sideways on the burnout; Hot Rod got a nice picture of it,

but in terms of a decent burnout it sucked:

I had noticed pushing the car around on the trailer and in the pits that one of the brakes was making some noise like it was dragging,

and I suspected as the car went sideways on the burnout that the left front brake just wasn't holding. Oh well, the purpose of the first

pass was just to get some air/fuel data, so I rolled up to the starting line and staged. The tree came down and I launched on the last

yellow. The car spun some one the line but the engine felt strong. It continued to spin going down the track and I was having some difficulty

keeping it straight. The shift light flashed and I went to second, but then it flashed again, I pulled the shifter back and - it didn't move. The car

didn't shift into third, and an instant later I hit the rev limiter and had to let off. I coasted down the track the rest of the way to a 13 second ET

at 55 MPH. Not a great start.

After picking up my time slip I went right back to the staging lanes, parked a little ways back behind the last car,

and started working the shifter back and forth to see what could have gone wrong. I have a new transmission in the car this year, and needed

to make a new shift lever for it to use the stock Mustang linkage. I thought that this may have been the problem, but the shifter worked

flawlessly while I was sitting there in the staging lanes. After a couple of minutes I came to the conclusion that I just hadn't depressed the button

on the stock shifter far enough when I went to do the 2-3 shift. The valve body in the transmission is a reverse manual, and you start in first gear

in the stock Drive position. On the 1-2 shift you shift from stock Drive to stock second, and you have to depress the button but pull the shifter back

only to second; its very easy to make a 1-3 shift rather than a 1-2 shift, especially when the car is weaving around on the track and jamming you

back in the seat. I cheat this by not depressing the button all the way on the 1-2 shift, and this seems to make it easier for me to hit second without

going all the way to third. But if you are not careful, you can not depress the button enough, and then the shift lever won't move. I was pretty

sure within five minutes of getting back to the staging lanes that this is what had happened on my 2-3 shift, so I was anxious to try again.

That lazy trunk monkey (

) was nowhere to be found, so I called him and had him bring my laptop over to the staging lanes. I pulled the SD card out of

the MS3X, and once Joel brought me the laptop I fired it up to look at the data. For some reason the computer had trouble reading the log on the

SD card, and I sat in the pits for 20 minutes trying to get the log to download with no success. Finally I decided to turn around and drive back to the

pits, to work on the problem there. But when I turned the key, I got the dreaded starter solenoid rapid clicking. Out of battery?? Of course at the

track I'd had to start up, run briefly, and stop again to stay in line in the staging lanes, but I thought my battery was in good shape with plenty of

capacity. Jack Miller was a couple cars behind me and I asked him for a jump but he had a boost box so he just lent me that. The car started with the

boost, but the engine was running like crap; it seemed like it was missing on at least a couple of cylinders. What the hell? I feathered the throttle to

keep the car running, did a U-turn in the staging lanes and went back to the pits.

With the car shut back off I decided to just work on one issue at a time. It was already past 11:00 AM, and the track was going to close for racing at 2:00,

so I had a limited amount of time to get the car back up and running right again. I went back to the datalogging instructions for the MS3X, figured out

what I had been doing wrong, and got the data file downloaded off the SD card. When I looked at the A/F data I was shocked; it said I was running way,

way lean, about 15.9:1 or higher during my pass down the track. I didn't see how this was possible; I had been very careful about setting up the injectors,

and when driving around on the street last week I'd been seeing A/F numbers in the 13:1 range. Now I was suddenly very concerned that I'd run the motor

too lean and hurt it.

Joel and I decided we'd better pull the plugs and look at them, and I wanted to pull the valve covers too to make sure everything

looked OK there. Within about a half hour we had the valve covers off and checked the valvetrain; all the springs and rockers looked good, which was a

relief. Next we pulled the plugs one at a time. On the left bank they all looked dead white; no doubt that the engine was running lean. On the right bank

they looked slightly better, but not by much. The good news was that none of the electrodes showed any sign of burning or melting, so I figured the engine

was probably OK. But I had no explanation for the lean condition, and no explanation for why it was missing.

We re-assembled the engine, and just on a lark I tried to start it. This time it fired right up, but was still missing terribly. I had Joel go around the engine on

both sides while I kept it running and he listened for any bad sounds. Outside of the miss, he didn't hear anything. With the engine shut back off we

discussed the problem and tried to come up with a diagnosis that made sense. By this time it was close to 100 degrees at the track and we were both

dripping with sweat; not the ideal situation for trying to debug an engine problem. Finally we decided to check for spark on all the plug wires. I restarted

the engine again and Joel went around to each plug wire with the timing light, looking for flashes. On the right bank he got flashing on all the cylinders, but on

the left bank there was nothing. So, the engine was running on four cylinders! No wonder it sounded like crap. I tried to think of what could be causing this

problem, and the only thing I could come up with was the EFI box. Was there some issue with that?

I had a spare EFI box, but the one in the car was mounted way up under the dash to keep the wiring out of the way. I sure regretted that mounting location

now. I crawled under the dash anyway to unplug the two main wiring connectors from the box and pull them down so I could plug the new box in. When

I pulled the first connector off, it came apart in my hand. The connector has a two piece metal shell surrounding it, held together with a couple of small bolts, and

one of the bolts was loose while the other one had come completely out. The shell of the connector was just rattling around on the end of the cable. I spent a

couple minutes looking at it; could this be the problem? In the end I concluded that it wasn't; all the wires were still attached to the pins, and there were no exposed

wires that could have grounded on anything to cause the problem. I pulled the other connector, which was intact, and the MAP line, and plugged everything into

my new MS3X box. I hooked up the computer to the box and opened the software.

I was met with something like 39 different error messages, mostly relating to the fact that the software on the computer was set up for a certain firmware version, and

the firmware in the new MS3X was different. The software wanted to know how I wanted to handle all this? I didn't really have a clue, but I went through all the error

messages and made the best guesses I could, thinking that I would have hooked this box up to the car before the race if I'd have known it was going to go through

all this. Finally I got through all the warnings and error messages. I tried to start the car - and got the starter solenoid clicking again.

By now it was after 1:00 PM. Joel went off to try to find someone with a battery charger or jump box we could borrow. After a couple minutes I got back in the car and

tried the starter again. This time after clicking rapidly for a few seconds it cranked the starter, but the engine didn't fire; seemed like the new EFI box was just not

configured properly to work. After all the error messages I'd received it was no surprise. I decided to put everything back together with the old EFI box, which took quite

some time because of how inaccessibly the box was mounted. About the time I got this done Joel came back with a guy who had a gas powered generator with a

battery charger built in. We let it run on the battery for 15 minutes and then started the car again, but of course had the same miss as before.

There wasn't much time left to race. I figured I could hand in the time slip I had to stay in the event, but there was no way I was driving to Indianapolis in the car with

four cylinders not running. It seemed like there was no option except to drop out. I was standing there in the pits staring at the car when Keith Turk, the race director,

rolled up on his pit scooter. "Are you out?", he asked. "I think so", I said. Keith said "Oh, OK".

I know Keith pretty well, and he is a funny guy, and I like to give him a hard time. I said, "Gee Keith, you could at least say you're sorry to hear that or something." Keith

looks at me, smiles, and says, "Dude - I am NOT that guy." I just broke out laughing; it was a real day brightener for me. Joel and I laughed about that all the way to

Indianapolis.

At that point I made the decision to throw in the towel; I wasn't going to run down the track again lean, on four cylinders, and I didn't think I could get the car fixed for the

trip to Indy. I was going to start putting stuff back in the trailer and getting the car packed up when Eugene, the guy driving Jack Miller's second Cougar, came over.

Apparently Jack had an engine problem and needed some gaskets, so I walked over to his car to see if I could be of some help.

When I got there Jack had the number 8 plug out, and water was running out of the spark plug hole. Not a good sight to see. Jack thinks that this car is capable of running 9s,

but it has Dove heads on it and I have seen this problem with Dove heads before. However, there was some chance that it was just a head gasket, or maybe an intake

gasket. Jack was trying to decide what to do, but with an FE in a Cougar with head studs pulling the head to change a head gasket was pretty much out of the question.

Jack didn't have a head gasket anyway. I offered him my spare intake gasket set, which may have worked on his heads, but he had kind of decided to give it up at that point

and just race the car that Eugene was driving. So, I went back to the Mach 1 to get it ready to go back on the trailer.

Joel pulled the truck and trailer out of impound and we had everything loaded up by 3:30 or so. Curt Johnson had stopped by on his way out of the track and told me he ran

a 9.13! Curt says his car weighs 3000 pounds with him in it, and mine weighs 3600 pounds with me in it. Hard to compete with such lightweight competition, and I'm pretty

sure that Curt is the odds on winner assuming he can make the drives. The next race was at Indianapolis and I had a hotel room reserved there, so we

decided that rather than go straight home we would spend the night at Indy, then watch the Drag Week action on Tuesday morning before we headed home.

On the way back to Indy in the truck I kept thinking about the problems with the car. It had been over a year since I wired it, but it dawned on me during the drive that each

bank of coils has a relay up under the dash that feeds power to the coil packs. If that relay had gone out for the left bank of coils, that would explain why there was no spark

on the left side of the engine. A little later Scott Clark called to see how I was doing, and I told him about my suspicions. He suggested I just check for power at one of the coil

connectors on the left side when the key was switched on, and that would tell me if power to the coils was the issue. Joel and I rolled into the hotel around 8:00 and after

dumping our suitcases and laptops in the room, we went back out to check this. Sure enough, the right side coils had 12V, but the left side coils didn't. So at least I knew where

to start looking for the miss problem. Unfortunately, like the EFI box, the coil relays are tucked way up under the dash where they are not really accessible. I'm going to have

to spend some time changing the wiring around in the Mach 1 to make all that stuff easier to get at.

Tuesday morning Joel and I headed for Lucas Oil Raceway to see the racing action. Here's a picture of the starting line from the stands:

Joel remarked that it is really fun to spectate at Drag Week because you see such a wide variety

of cars running down the track. On Monday one of the unlimited cars had run a pass in the 6.70s, and he did the same thing on Tuesday; the pass was awesome, and I would have

loved to be rolling down the road behind that guy. I think those were the fastest passes ever at Drag Week; the car is basically a Pro-Mod Camaro body with turbos and a big block

Chevrolet I think. On the track you get to see early and late model cars, gassers, imports, you name it. There were two front engined Corvairs there on Monday that I imagine were

also there Tuesday, although I didn't see them. Here's a pic of Larry's car on the starting line at Indy:

Here's another 69 Mustang running at the track. This guy was from Canada, and drove down for the event. On the way he had to change a camshaft LOL! He got to Beech Bend and

ran an 11.60 something, best time ever for his car. He was loving life when I talked to him on Monday:

After watching the racing for a while from the stands I spent the rest of the morning wandering the pits and taking pictures. Here's a picture of Curt Johnson's car, which

ran a 9.10 on Tuesday at Indy. There was another guy in the class with a mid 9 second Mustang with an LS engine in it, but I guess he changed to Super Street on Monday,

so I think Curt is the only guy in the class running nines.

The gasser cars were pretty cool; here's some photos of those:

The car that Joel is building is very similar to that last one, so he spent quite a bit of time talking to the owner and asking questions about the front axle and shocks. There was also

a pretty nice mid 60s Ford pickup in the pits. I didn't see a number on it so I don't think it was a competitor, but it was worth a photo nonetheless:

I spent a lot of time in the pits talking to Mike Crow and Jeff McConnell about various topics, and also ran into Mike Moore and Tom Posthuma again also. Finally around 11:30 local

time Joel and I decided to hit the road. We were walking out of the pits back to the parking lot when this guy comes running up to us; he was with a group of guys running a small

block late model Mustang, and we'd gotten to know them when we were parked next to them during registration. He'd seen me changing pushrods on Sunday, and knew that

I had T&D rockers. In his hand he held a broken T&D rocker from his engine and wanted to know if we had any spares. He followed us back to the trailer and I dug out my spare

rockers, but they were pretty far off from the small block versions, and it was clear that they wouldn't have worked for him. Too bad, they were nice guys. I hope they get

something worked out for there car.

Joel and I hit the road and got back to Minneapolis last night. I'm trying to keep positive on this year; I didn't really break the car, and I got to see all my friends at Drag Week

again, and now I've got a couple of days off to debug the problem. But despite all that I'd rather be racing in St. Louis today, and running down the road to Memphis

tonight. I'm going to have to try to get better prepared for the event next year...