Will the RE version of the heads work in a 1964 Galaxie with stock front suspension (assume custom built headers)? Putting aside the tunnel ram intake, will either, or both, of the other two intake options fit under the flat hood, and if not, will they fit under the tear drop bubble hood?

Does the slaughter level of performance apply to both the SE and RE versions of your heads, or only to the RE version? Will the SE & RE versions blow away the BBM CNC ported heads across the lift range, or mainly at maximum lift?

The "slaughter level of performance" LOL! Cracks me up

I don't want this to sound like an advertisement, but here is the deal with my heads. They have an unfair performance advantage over all the other heads that are currently out there. The whole idea behind the head package is similar to the idea behind a Yates style 351C head package, where the ports are raised so high that a special intake manifold is required.

On the FE Power heads the intake port is raised nearly 1-1/2" over a factory medium riser port. It is higher than a high riser. The valve cover rail is also raised proportionately. This allows a very generous, smooth short turn on the port.

In addition, the port is straightened out. Stock FE intake ports, except cammer and tunnel port ports, all hook towards the center of the engine and aim the intake charge at the cylinder wall. My heads straighten the intake port so that the cylinder wall is less of an obstruction to flow.

Also, the valves in my heads are moved from the stock location. This again gives room for a better chamber, and better flow into the cylinder.

The net result is a head which flows 60% more than an Edelbrock head, with the same port cross-sectional area. The flow is dramatically improved at all lifts over 0.200". For example, stock Edelbrock intake lift at 0.300" is 182 cfm, FE Power head at 0.300" is 233 cfm. At 0.400" lift, stock Edelbrock intake flow is 214 cfm, FE Power intake flow at 0.400" is 294 cfm. At the .100" and .200" valve lifts, the numbers are close to the same, although the Edelbrock head is slightly better at 0.100" lift (89 cfm vs 77 cfm), and at 0.200" lift the FE Power head is slightly better (160 cfm vs. 156 cfm). Flow numbers at 0.700" lift for the stock Edelbrock intake port are 260 cfm, and for the FE Power intake port the flow numbers at 0.700" lift are 403 cfm. Again, this is with the same cross sectional area for the port opening. It is a huge, huge improvement.

I don't have flow data for BBM CNC ports, so I can't compare to those. However, I assume that to make good flow numbers, those ports have to be enlarged. This means port velocity will be reduced due to a larger cross sectional area of the port. This will reduce the port's ability to flow as the intake valve is closing. It's not just about flow, after all, flow and port velocity, and of course the valve job, are all very important.

I think that the RE (Raised Exhaust) version of the FE Power heads will make more power than the SE (Stock Exhaust) version, just because they flow a little better, and also a better header design can be fabricated without the shock towers in the way. But the SE exhaust port still flows way, way more than a stock exhaust port, so despite being down 20 cfm from the RE exhaust port, it is still capable of supporting a big power level. In fact, the SE exhaust port flows 248 cfm at 0.700" lift, which is almost as much as a stock intake port flows! Imagine that...

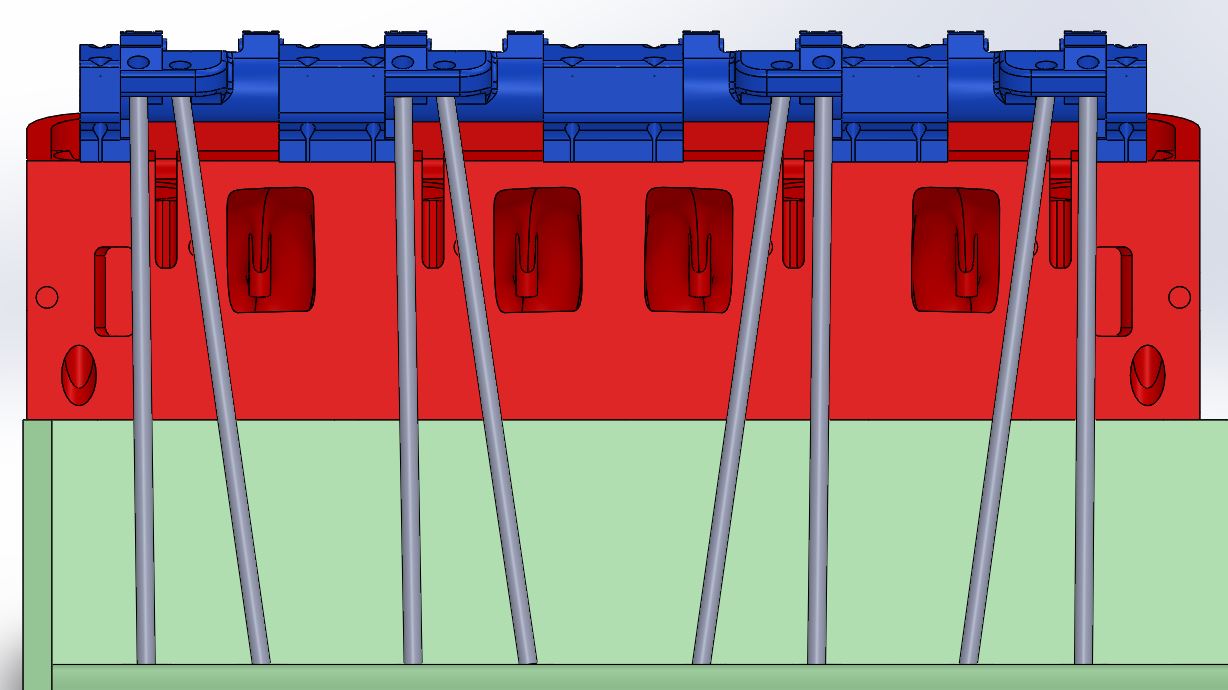

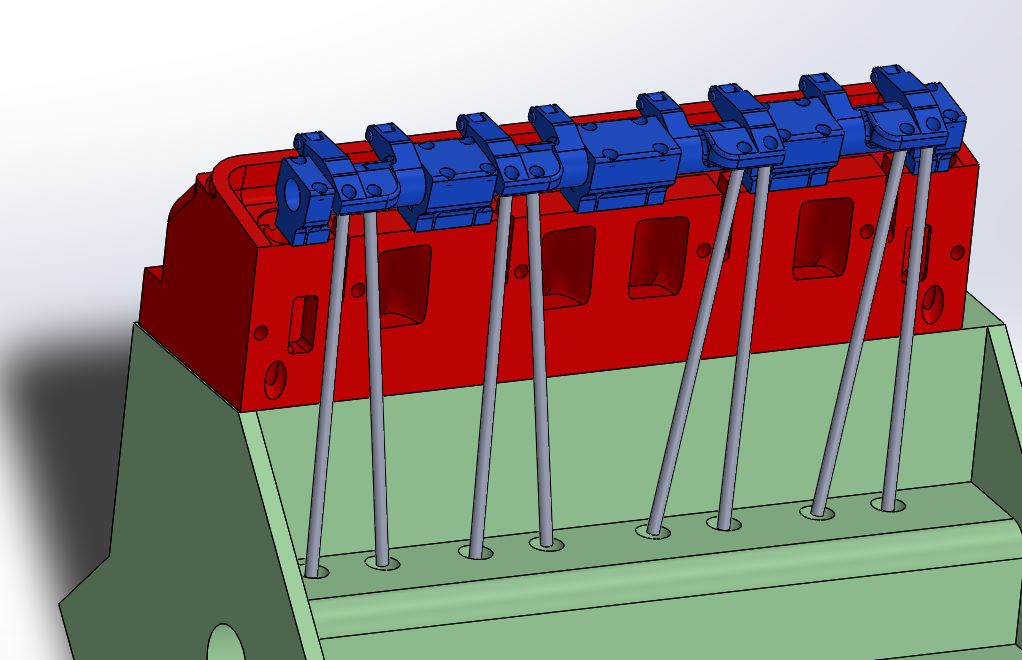

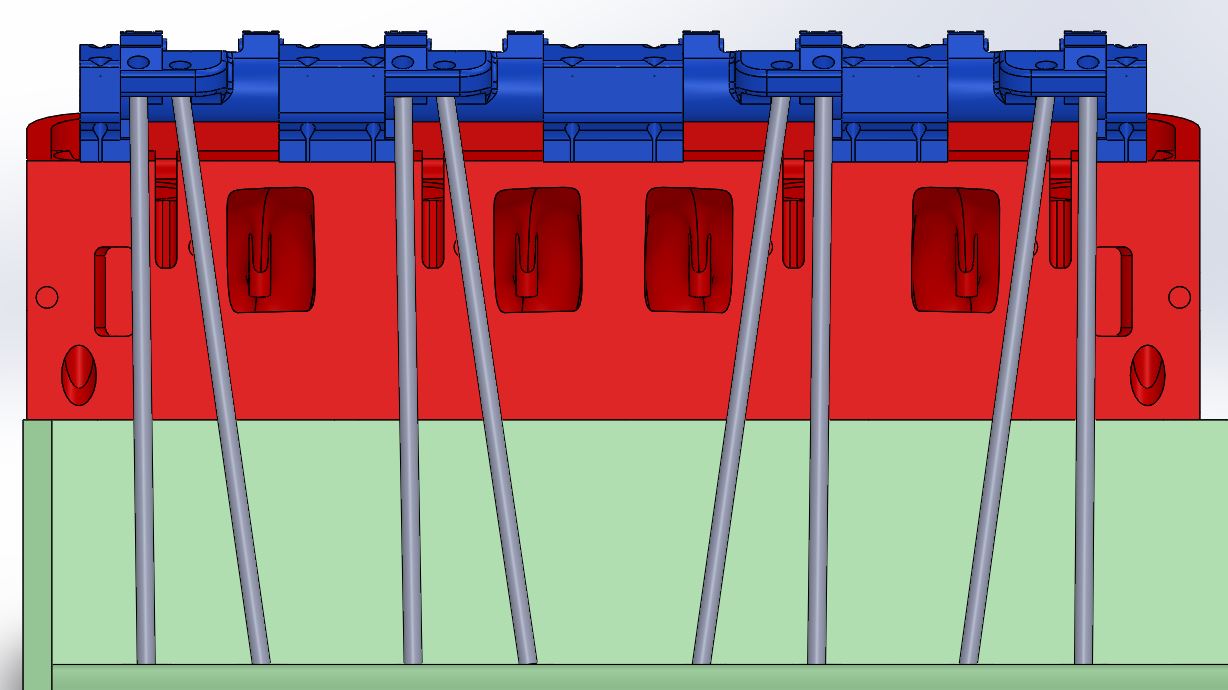

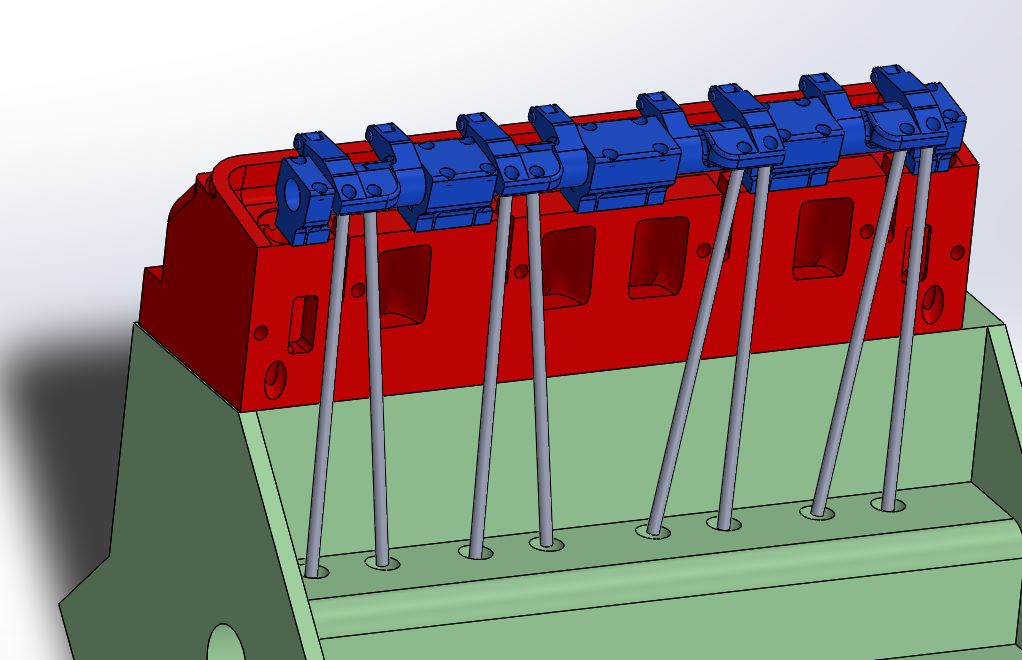

So, here's the downside of the FE Power heads: No stock FE intake will fit, and stock FE rocker arm assemblies will not fit. One of my special intake adapters, with raised ports and a raised valve cover rail, will be required with these heads. Also, either a custom fabbed intake, or one of my three intake versions, will have to be used on the intake adapter. And, in order to miss the port with the pushrod, a large offset is required on the intake rocker. Here are two CAD drawings of what the pushrod configuration looks like:

As a result of this, the whole package, including heads, intake adapter, and rocker arm assembly, has to be purchased.

I hope that clears up the questions without sounding too much like an advertisement. I'm getting pretty close now to being ready for dyno testing with these heads, so with luck I'll have dyno data and be ready for production by the FE Reunion at the end of April. We will see...