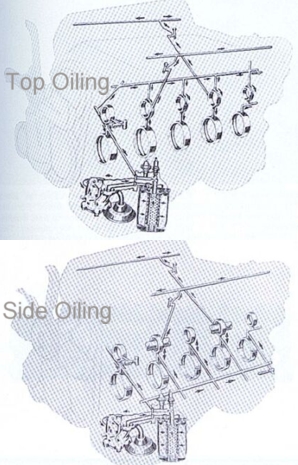

I've been thinking a lot about this and there has to be a reason why Ford would install a pressure relief spring in the block, rather than just relying on the oil pump relief spring. Below is the layout for top and side oiling FE's.

So what would be the cause? Pump loss is due to surface finish, distance, elevation changes, number of bends and what type of transitions are present. What this turns into, is pressure drop the farther you get away from the pump. Resistance will build up pressure, but that pressure is not exactly uniform, due to pumping losses. So resistance to flow builds up pressure at the pump, but that does not mean said pressure will be seen at the end of the passage. So Ford must have figured that the best place to regulate the pressure for normal operation would be at the end of the flow, ensuring that the maximum-minimum pressure seen anywhere in the engine is at the end of the oil gallery, rather than before oil even reached it. That last sentence can sound a little confusing, but the point of the design is to regulate the oil pressure at the end rather than the beginning, in order to keep oil pressure where it needs to be for all parts of the engine. So you don't stop the pump at say 65 PSI which will eventually drop as the oil reaches the back of the engine. By regulating the pressure at the back, you know that the whole block receives a minimum of 65 PSI before the relief opens.

This is all based off of the theoretical functioning of the pressure relief spring at the back of the engine. How much the oil pressure drops between the pump and this spring is hard to know without putting a gauge in place of the relief spring. It could very well be a preventative measure, as engineers like to think of every possible way there could be a problem.