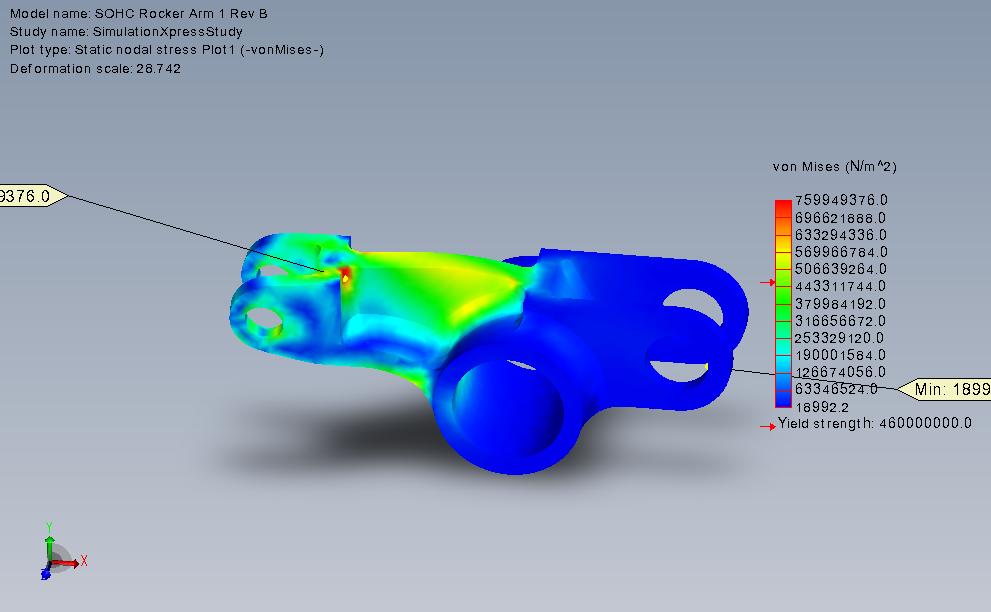

This thread is really starting to get engineering oriented, as I hoped it would; this is pretty cool stuff if you ask me LOL! Both Mario and Bill Conley have done some analysis work on the rocker arm design. This is FEA (Finite Element Analysis) stuff, and shows where you can get stress loading on the rocker arm. Red on the analysis indicates high stress, and blue indicates low. Mario felt that the rib on the rocker arm needed to be thicker based on the stress analysis, so he modified the rocker arm drawing to increase the thickness by .060". Here are his two stress analysis results, with the original rocker design and the modified design with the thicker rib:

Bill did a dynamic analysis on the rocker, and sent me a couple of videos showing an exaggerated view of how the rocker deforms, at zero lift and also at peak lift, with a 1000 pound spring load. Links to these videos are below:

http://fepower.net/Photos/Posts/BillC1.wmvhttp://fepower.net/Photos/Posts/BillC2.wmvBill's comment was that the rocker design looked acceptable as is, especially given the use of the rocker. Bill also thinks that the zero lift stress analysis is more important than the full lift analysis, because at zero lift the rocker arm has to start the valve and spring package moving, while at full lift the inertia of the valve and spring take some of the load off. Bill's analysis showed a very slight twist in the roller end of the rocker when the load is applied, but nothing too substantial. The deflection of the arm at 1000 pounds is 0.017", which is a little higher than the T&D arm (0.010"), but is probably the result of the smaller diameter rocker shaft, and the resulting smaller diameter of the body of the rocker arm.

It is interesting that the results of the FEA work is not quite the same, and points to differences between how the two analyses were set up.

In any case, either as is or with minor modifications it looks like the rocker will work out as intended. I actually kind of like Mario's modification to make the rib thicker, because I'm going to have to drill a hole through that rib in order to oil the valve tip roller. Making the rib thicker will make drilling or EDM-ing the hole easier. That hole is also not part of the analysis, because it isn't drawn into the arm yet. My plan on this was to wait until I had an aluminum rocker machined, test fit it on the head, and make any required adjustments to the design, and then worry about the oil holes. So we will see how that works out...