Another "guess the horsepower" game. Same rules as the last ones.....closest without going over wins some Lykins Motorsports paraphernalia. Again, as before, I will be posting UNCORRECTED numbers, so use that little tid-bid in your final guess. I will probably ask Jay if he will do the calculations and post corrected numbers as he did last time.

I'll even add another incentive: if anyone guesses the exact horsepower and the exact peak horsepower rpm, they will receive a free set of my new non-adjustable roller tip rocker arms.

I'm waiting on pushrods and a few odds and ends to show up, but I plan to have this on the dyno around the first week of December. Long block is assembled and just need to do a little mill work on the intake manifold.

As for the engine:

*Block is a C6ME block, 4.060" bore, with a 10.145" deck height. Block has had cylinder vents drilled in the block's bulkheads. Bored/honed with torque plates, square decked with a BHJ fixture, and align honed with ARP main studs. Block has been half-filled with Hard-Blok. All major galleys have been drilled/tapped for screw-in plugs. Block has been fitted with bronze lifter bore bushings, with BHJ fixture.

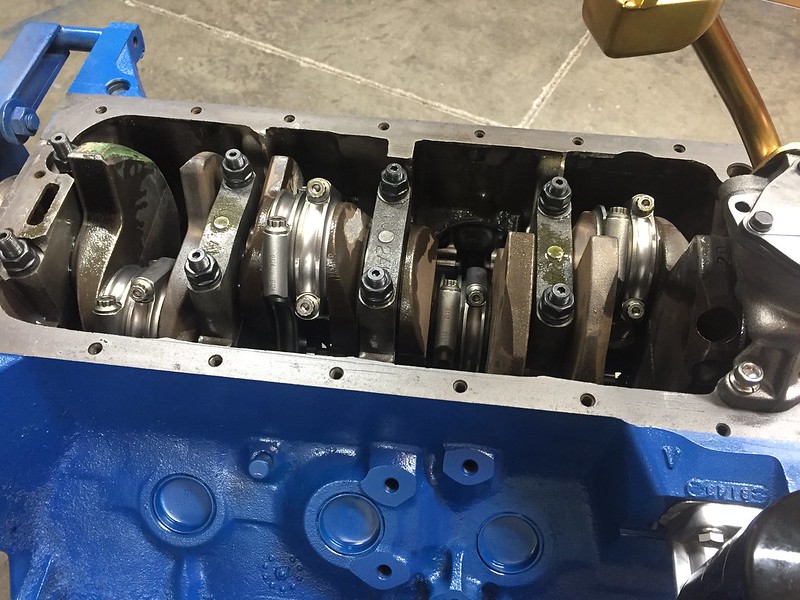

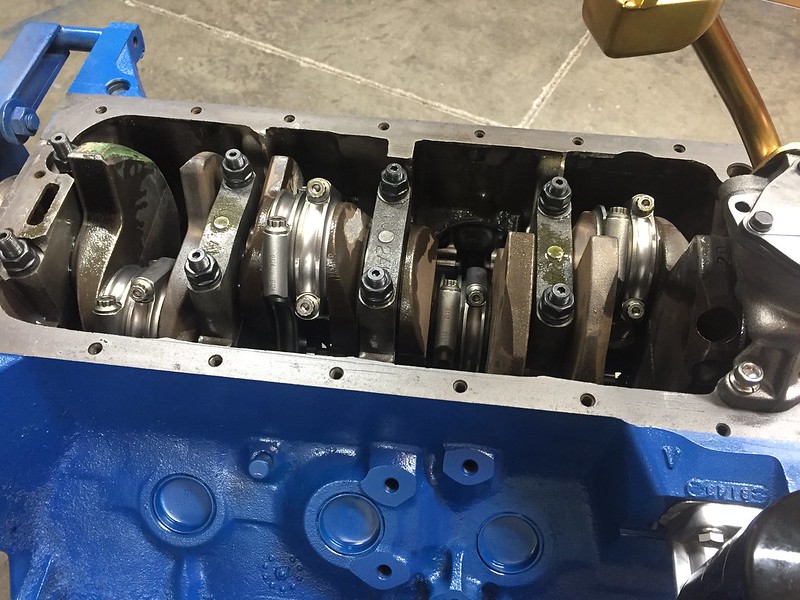

*Crankshaft is a factory 2U 390 crankshaft, cut .020" on the rods and .010" on the mains. Has been balanced with new pistons/rods/etc.

*Connecting rods are Molnar 6.490" rods, with factory FE rod journals.

*Bearings are Calico coated Federal Mogul rod bearings, Federal Mogul 125M10 main bearings, and Durabond FP-33 camshaft bearings.

*Cloyes billet timing set

*Pistons are custom Racetec pistons, with a 4cc dome. They hang .010" out of the block.

*Piston rings are Mahle 1mm/1mm/2mm rings.

*Oil system consists of a Melling HV pump, with a Milodon pickup and front sump oil pan.

*Cylinder heads are C8OE-N heads. They are the end result of some spare parts laying around and quite a bit of labor. They have been steelabrated, had bronze guides installed, and have been ported. Intake valves are titanium XCeldyne valves, 2.080" diameter, with a 7mm stem. They weigh 85g. Exhaust valves are custom Ferrea stainless valves, 5/16" stem, with a 1.630" head diameter. They also weigh 85g.

Flow numbers are as follows:

.1 62/54

.2 126/107

.3 197/134

.4 260/156

.5 279/171

.6 281/183

.7 289/191

Intake port volume is 162cc.

*Compression ratio is 12.1:1

*Valve springs are Comp Cams conical springs with PAC titanium retainers. Spring pressures are at 200/500.

*Camshaft is one of my custom billet core hydraulic rollers. 259/267 @ .050", 114 LSA, 107 ICL, .630"/.630" lift.

*Lifters are Morel hydraulic roller lifters.

*Pushrods are custom Trend 3/8", .135" pieces, with H13 ends.

*Rocker arms are my new non-adjustable roller tipped pieces. I have added Precision Oil Pumps billet stands and end stands.

*Ignition includes an MSD Pro Billet distributor that has been fitted with a steel gear and locked out.

*The top of the engine consists of an as-cast BBM Tunnel Wedge, topped with a pair of 1" Super Suckers, and a pair of Drew's 1850 carbs.

*I will be turning a mechanical water pump off the crankshaft.

*I will be using a header-vac setup.