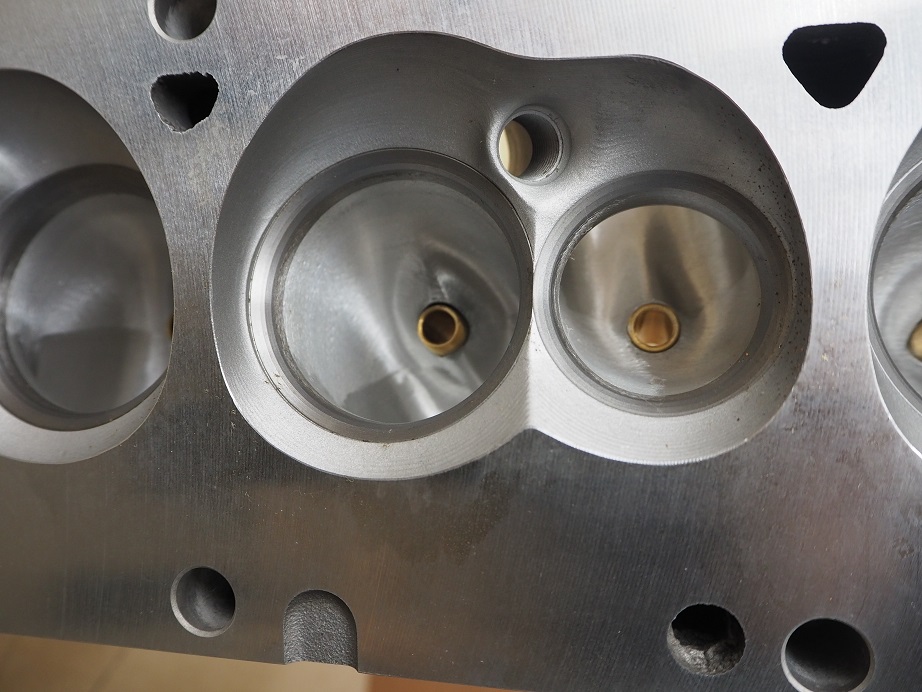

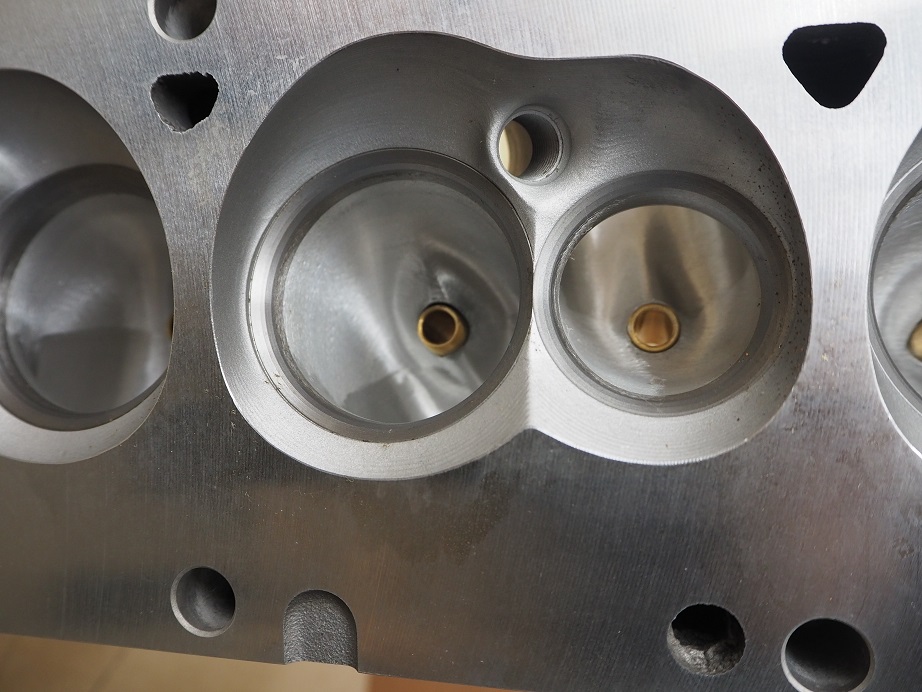

Starting to sell some of my stash of personal items. This is a complete cylinder head package for an FE, with the best parts I could buy when I purchased them in 2006. The heads are the Blue Thunder medium risers, the early ones, not the ones with the huge rectangular ports. I purchased these CNC ported from Barry R at Survival, and used them on the supercharged engine in my Mach 1 that I ran at Drag Week in 2007. I don't have flow data on these heads, but when I bought them Barry said they flowed around 360 cfm on the intake, and I have no reason to doubt him.

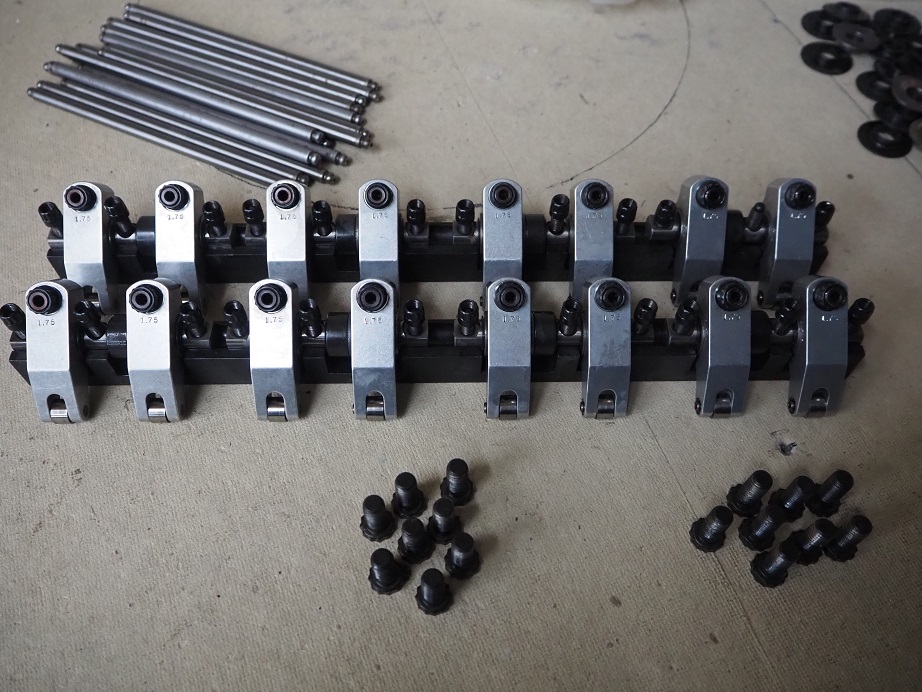

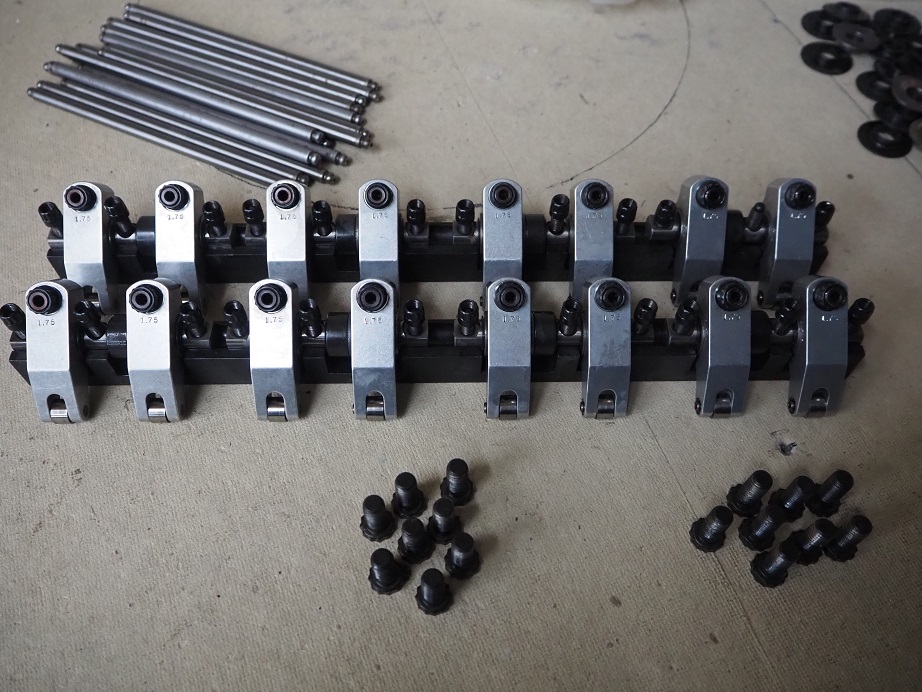

Since the engine was supercharged I went with Inconel exhaust valves for durability, and normal stainless steel intakes. I had the chambers and valves coated at Swain Technologies, and fitted the heads with springs that were much heavier on the intake due to the 17 pounds of boost I was running from the centrifugal supercharger. The T&D rocker system, which is a dedicated system just for the Blue Thunder heads, uses the standard 1.75:1 ratio, with no extra offset on the rockers. On the dyno, with an air to water intercooler, the engine made 1030 HP. In the car, I couldn't get the intercooler to fit where I wanted, so it only made about 900 without it.

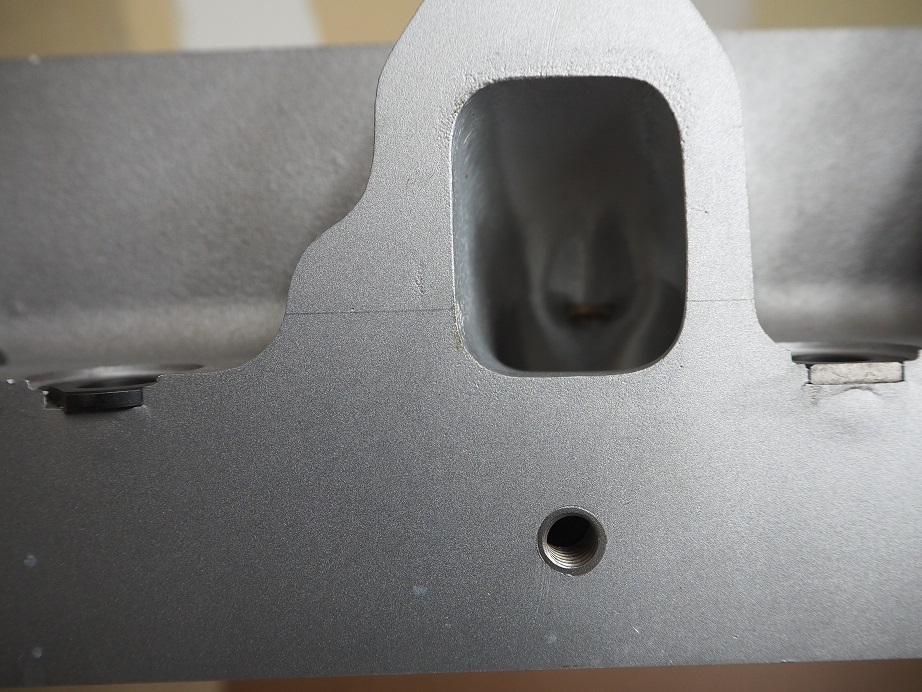

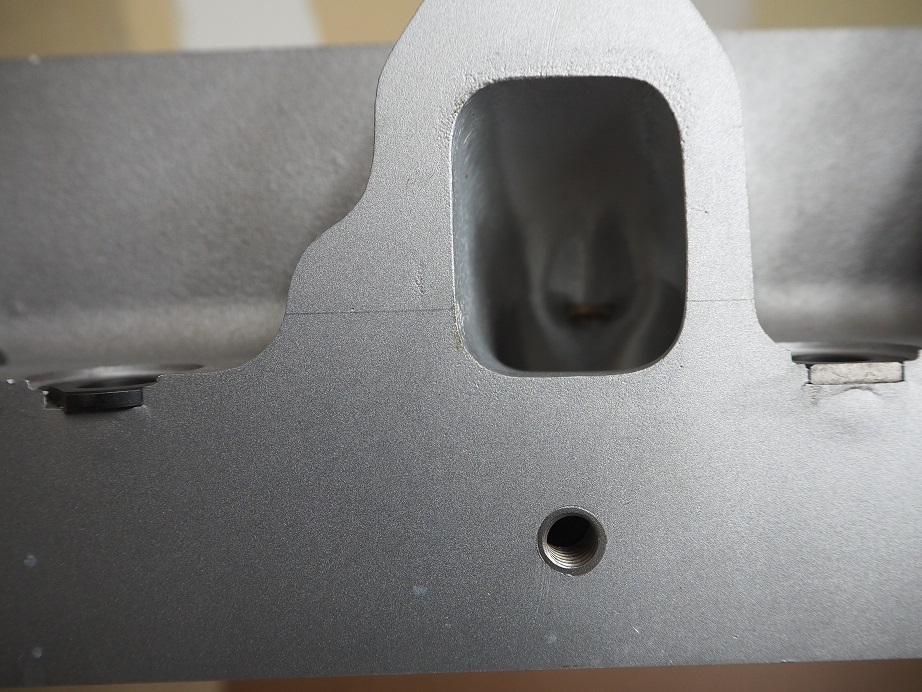

After Drag Week I had the heads gone through in preparation for reassembling the engine with them, but got bit by the high riser bug and went that route in the car. So, these heads have been sitting in plastic since about 2008. They have a new valve job, new surfacing, and several new valves because some of the old ones showed stem wear. The ports were also cleaned up in order to remove the CNC tooling marks. If you look carefully at the pictures you will see that the exhaust side of the heads has also been relieved about 0.100", in order to provide more clearance for the headers (Blue Thunder heads have the exhaust ports raised up just a little, so extra header clearance is good).

The valve springs, retainers, spring seats, and lash caps are included in this package. The exhaust springs measure about 180 pounds at 2.000", and 520 pounds at 1.300". The intake springs measure 280 pounds at 2.00", and 640 pounds at 1.300". This is using my somewhat questionable spring rate checker; wouldn't surprise me if they were off a bit one way or the other. The retainers are Comp Cams titanium retainers, and the spring seats are Comp steel seats.

The T&D system requires oiling through the pushrods, so I am also including the pushrods that went in the engine. Some of the pushrods have some rust spots on them that I've wiped away with WD40 and a Scotchbrite pad. I would not hesitate to use them again, but you may be fussier than me. There is one nut missing on the T&D setup; its got to be around here somewhere, but I have not been able to find it yet. Also, when you purchase the T&D setup they provide washer-like shims that can go under the rocker bar, to adjust rocker geometry; I don't have those either, but they could be easily obtained at McMaster Carr.

This is all really top shelf stuff that I had more than $8K invested in when new. I want $5500 for the package. I will not separate it. Shipping is extra. I can take a personal check, and also a credit card, but if you use a card I will have to add 3.5% for the credit card fee I get charged. Pictures are below. You can message me here, email me at jayb@fepower.net, or call the FE Power number at 952-428-9035. Pictures are below, and thanks for looking - Jay