Well...I measured my driveline angles with car in the air as it was during the install. The important thing is to have the car supported under the diff so it sits at approximate ride height. Doesn't really matter what angle the car is on.

After much research on driveline angles (and there is plenty of misinformation and lack of understanding out there) these are the rules I am playing by, There are only 2:

1) The output shaft of trans and input shaft of diff (yoke) should be parallel to within 1 to 1/2 a degree with the diff pinion being down that 1/2 to 1. Diff pinion angle is all a compromise. With a leaf sprung car the more hp and the more strip time it sees the more angle down on the diff pinion. As this is a street car I will shoot for the 1/2 to 1 degree down. This keeps the operating angles of front and rear unis very close to equal.

2) These shafts should be brought to within that tolerance in such a way as to try and ensure that the operating angle of the unis does not exceed 3 degrees. This is for a hottie. Standard passanger cars & 4wd's etc can tolerate angles up to 7, but angles within 1/2 to 3 degress are more desirable. Operating angles of 0 degrees are a no no.

End of story and no debate will be entered into. There is enough debate out there on other forums and beleive me I think I have read it all!

So here is a pic of driveline angles as measured with those 5mm spacers under the crossmember to 'clear' floor.

This means that either the output shaft or diff pinion has to come up about 4 degrees to make the angles parallel. If I take the pinion up 4 degrees then the operating angles of the unis become large (7 degrees). So obviously the desirable thing is to lift the output shaft, but the floor is in the way. Wanting to take it for a test drive without it shaking like a dog passing you know whats I made up some temporary 3 degree wedges to get the angles close.

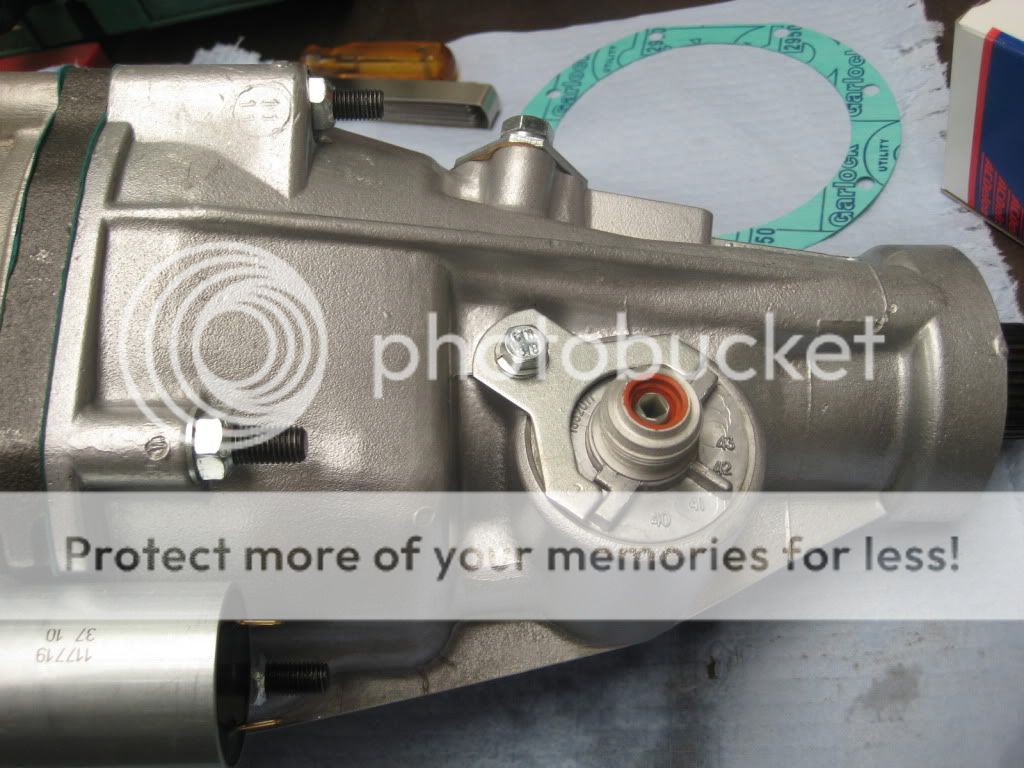

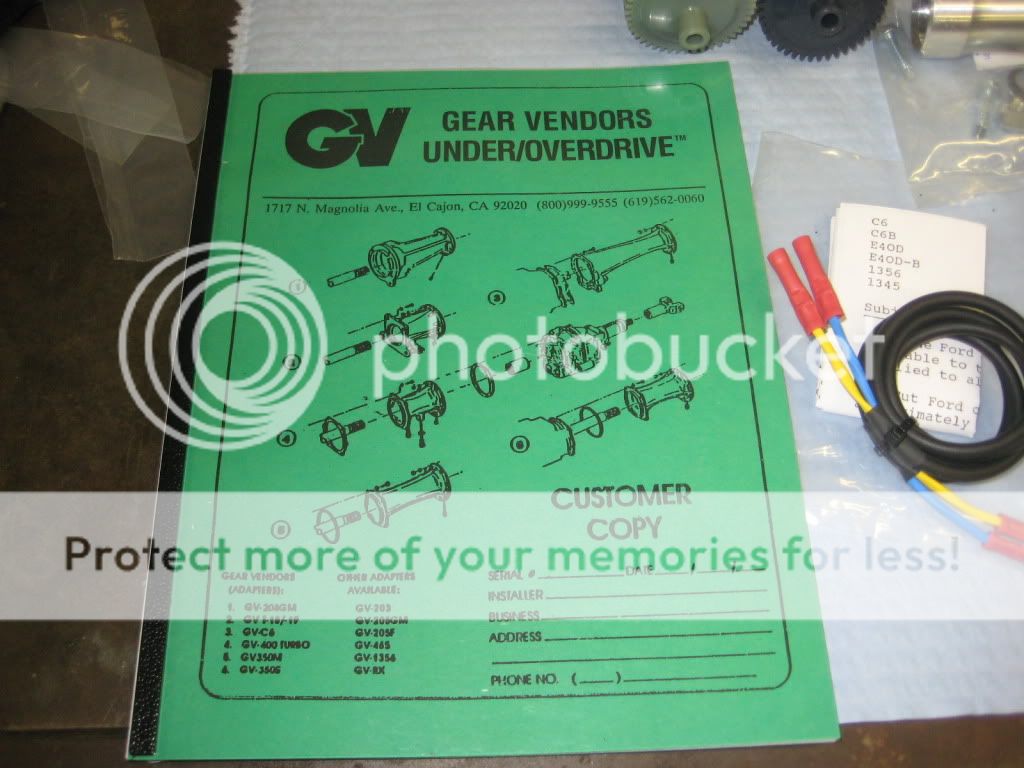

Installed

Also the speedo cable hits the floor at a bad angle as is and some massaging here will be necessary also. The unit appears to be loosely based around a GM TH400. I don't know whether all GM transmissions have the speed output pointing up but it seems bloody silly.

Speedo cable into floor.

So I took it for a short drive around a long block. All working properly and I think I am really going to like it. I didn't get on it as they recommend a short break in period and I wasn't really confident of the diff wedges either. Some small vibes but hard to tell what it is with unit on the floor. It was really noticable stationary at idle and just noticable cruising along so it may just be the unit touching the floor.

I got home and am very keen to get the floor sorted and the unit up so I can drive it with confidence and get stuck into it. So out came the interior.

Unfortunately Where the tunnel need altering is right under a brace. Still thinking about this one.

It's Saturday night. I'm gunna go have a bourbon! Cheers.