My winter/spring project started out as a "Quick and Dirty" mostly back yard rebuild (re-ring) of my 950 HP 565" A460 headed engine that has been together since 2011. It has many many running miles on it.

The build that went together 10 years ago this summer is as follows:

4.605 bore x 4.25 stroke = 565 actually 566"

A-460 Block

Crower/Ford Motorsport crank 4.25 stroke (.020 under)

Crower rods w/ BBC journal 6.536"

Modified A-460 angle milled with 2.40" Ti intake 1.88" Ex w/ 66cc chamber, 13:1 Compression

Carb: Old - Holley Barry Grant 1,050 (from 1991) It's been reworked a few times now.

Crower Roller cam (Danny Crower) 278/285 @ .050 with .433 lobe lift ( installed at 4* advanced intake opening at 30*) 109IC

T&D Shaft rockers 1.8 ratio

Manton Push rods 3/8" thick wall.

Arias pistons, gas ported ( Atomic ) 13:1

Akerly & Childs ring pack .043, 1/16th, 3/16th with a Tool Steel top ring

Stephs oil pan w/ kick out

Kaase oil pump

MSD crank trigger

Cometic head gaskets .045.

Single 1,050

948 HP at 7,200

I hurt a couple of piston running the nitrous back in October. Luckily I had two pistons sitting around for just such an occasion. In talking with my old friend Geoff Mummert ( 2019 EMC second place 289 Ford ) (he ported the heads on this engine around 2003) we were sorting out the 600" pump gas deal I want to build with him next year. We came to the conclusion that if we did a quick rebuild on the 565 there would be a few things that would carry over for the 600" pump gas build.

All was well and good until Geoff said, " Do me a favor. Don't die with that tunnel ram that you've had for 20 plus years still sitting on your shelf. How about using that thing and let's see if we can make 1,000 hp with it?"

I'm a sucker for a challenge .........

And so it began ......

We've been working on things for the past few months with cam selection, carbs getting rebuilt and all the rest.

We've challenged ourselves to see if we can make 4 digits at 7,200.

We made a pretty big cam change to see what would happen. We ended up ordering a custom Comp roller that's 275/276 @ .050 Lobe lift .455/.421 with a 1.8 rocker and ground on a 113* lobe sep.

Target for peak power was 7,200.

This rebuild started out so simple that I used a ball hone on the block:

I heated some Napa 10-30 oil up to 200* for the job:

We put new cam bearings in it and got some good rings from Akerly and Childs. I screwed up on the end gap and gapped the stainless top .043" ring at .041" as if I was going to run my 350 shot on it. It didn't beet that much. .035 would have done it.

Got the cam degreed in: Int Open 23* Close 71*

We made it up to Westech this past Thursday with both the single 4 and the tunnel ram and burned some Sonoco 110.

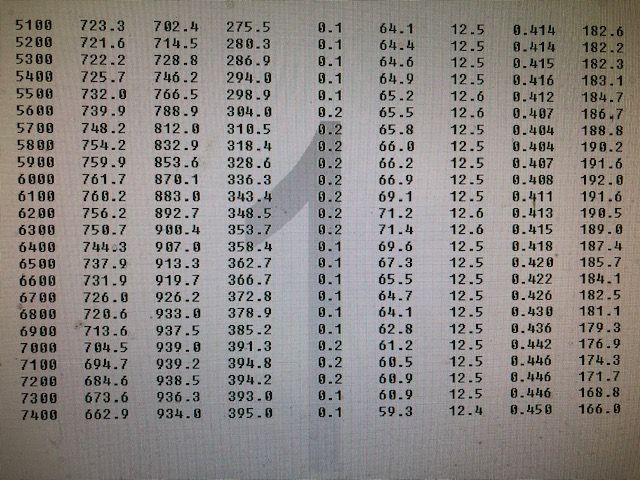

The single 4 made 939 hp at 7,200:

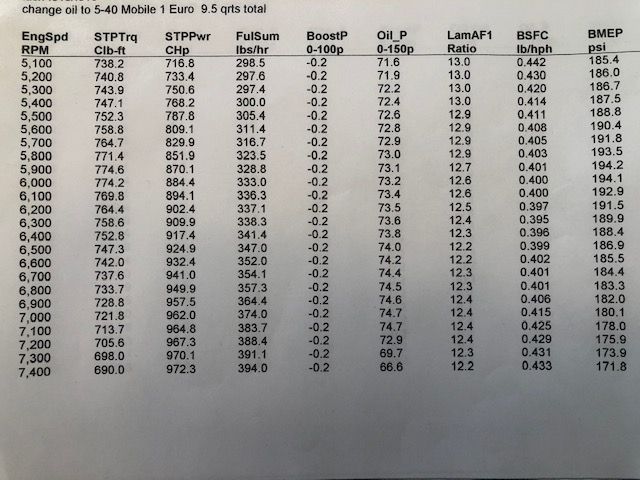

The tunnel ram made 972 hp at 7,400:

We were running a little Ford Taurus electric vac pump on the engine:

It pulls -4" static and was able to maintain -1.5" thru 7,400 rpm with the single 4. When we put the tunnel ram on we let the silicone set up as we ate lunch and then were running the engine without the vac pump turned on and on the 3rd run it blew out the rear China wall seal. We then turned on the vac to control the oil leak. It was able to pull -.5" vac thru most of the run, but went to positive .5" at the end of the runs.

We're going to do some work on the tunnel ram, install a GZ vac pump, advance the cam and head back to the dyno in a couple months. ... Might even take some Q16 with us. We'll see.

Here's a video of one of the 970hp pulls:

https://vimeo.com/530160429The Power Plant is for the boat: