I finally had a chance to go pick up my block Saturday. The 2hr 45min drive to Survival Motorsports was well worth it to meet Barry and Willie. But it wasn't just a pleasure trip, I had some stuff to drop off.....about 900lbs worth

I'll let you guys analyze the pictures. I'll just make a couple comments based on my impressions.

The weight on my scales, which are pretty accurate, was 262lbs. Easily, 10 of that could be lost if you were scrupulous in removing the cross ribs, boring, did a lot of edge breaking etc etc. Obviously significantly more than a stock block, but you can't expect a stronger block and the same weight.

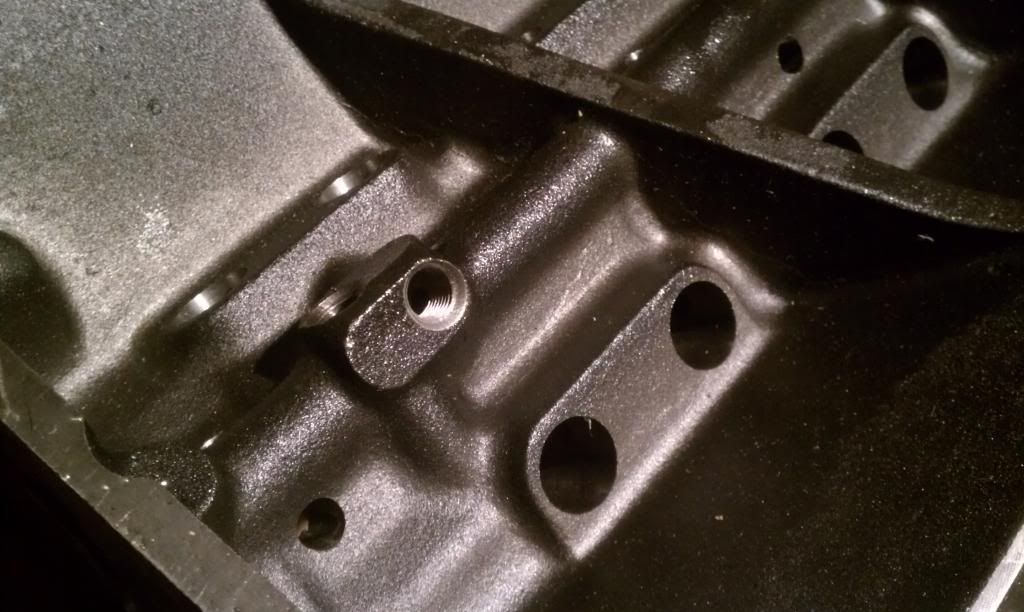

This is about the only flashing I saw that needed to be removed. Overall, a very nice clean casting. But like any fresh casting, it has razor blade edges and should have a complete edge breaking/chamfering of all machined surfaces.

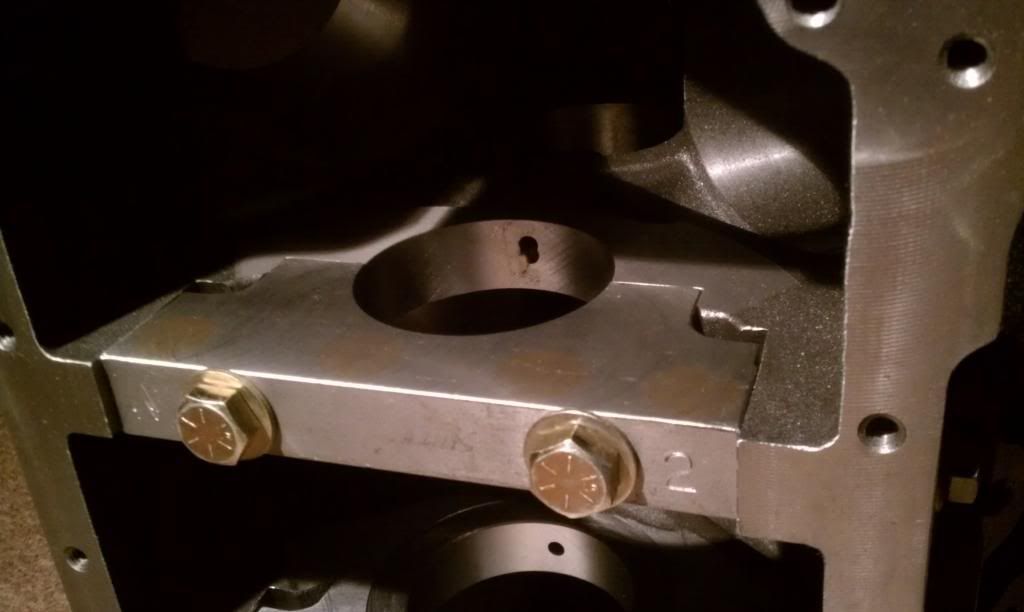

The siamesed cylinders.

Overall, I'm pretty impressed with the block and very happy with it. It will be a good strong foundation for a high HP engine.

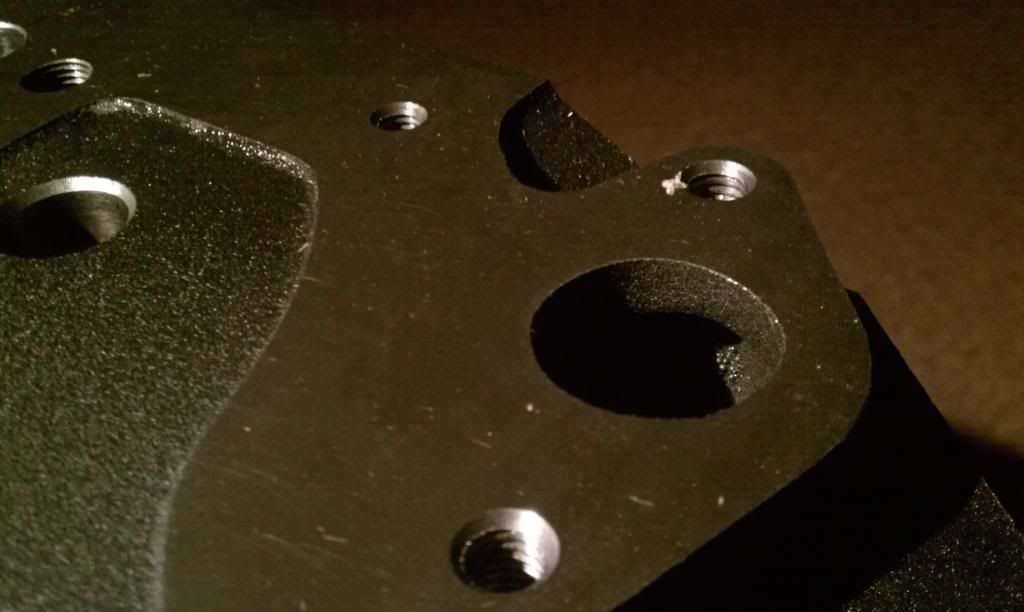

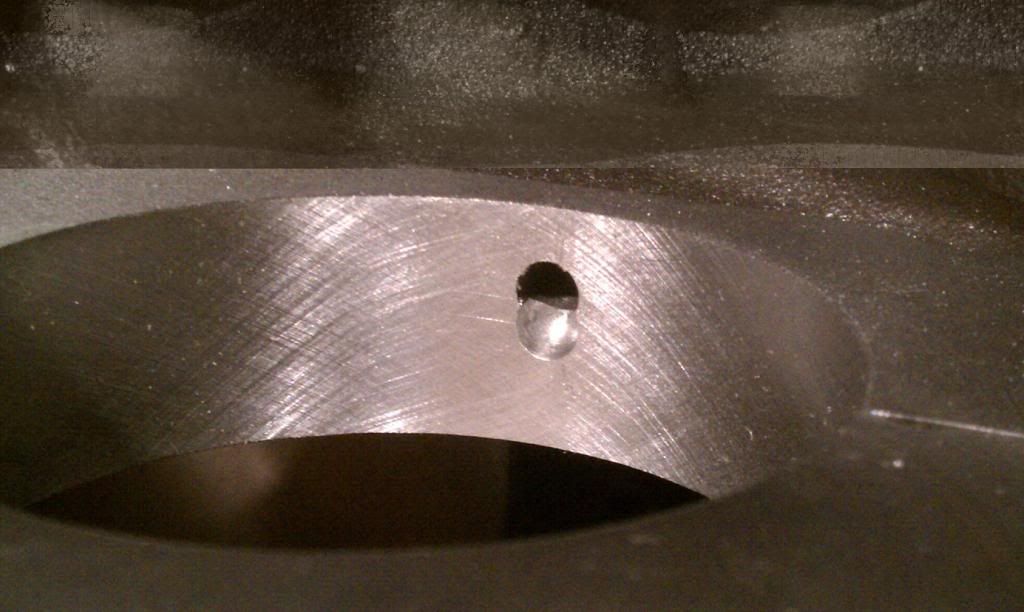

There is one issue that I don't like, It's the oil port from the pump to the filter adapter. There wasn't enough material cast on the back side (inside) of the block and the port broke through. A sleeve is installed, and that will probably work fine. I just don't like how it is a smaller port than the rest of the system to that point and beyond, so I'll probably enlarge it more. I'm sure it will probably be rectified in the next run....provided there is one. To me, it's not major and can be fixed. Actually it already has been by the original casters, but I may do what I consider to be a better fix. I actually doubt it's even a problem, but I'm a little anal about things. It in no way affects integrity of the block or any alignment problems.

I love the block and can't wait to get started on my next serious build.