Apologies in advance if y’all have seen this on another forum, going to try to condense it into one post in case there are any unique visitors to forums.

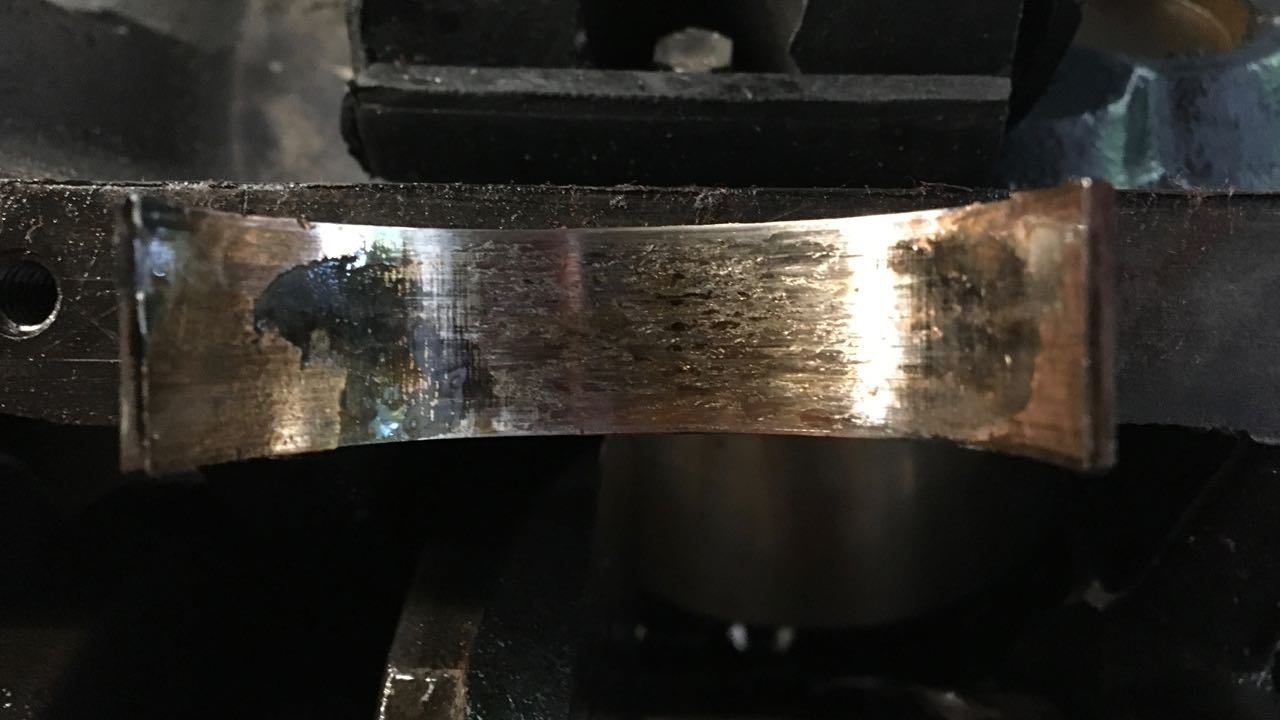

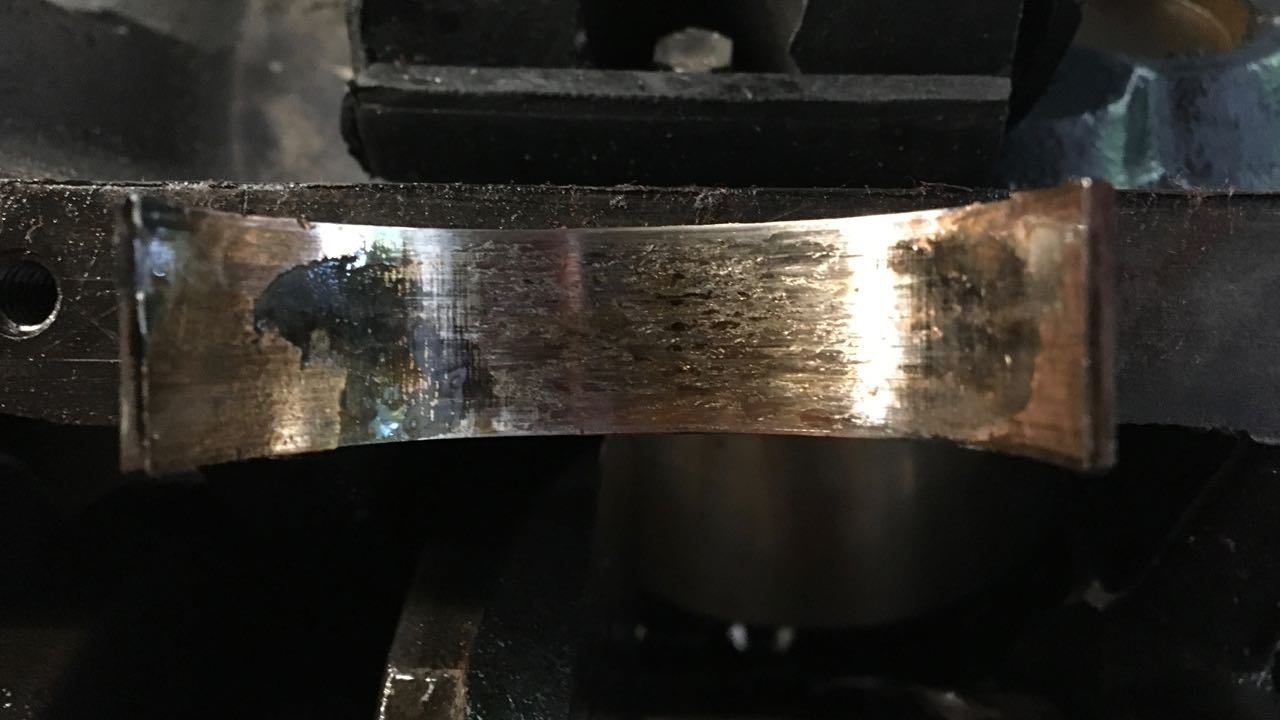

Seems like I’ve lost a Rod bearing in the 390.

I built this engine a number of years back (like 2005ish) but it has very few miles.

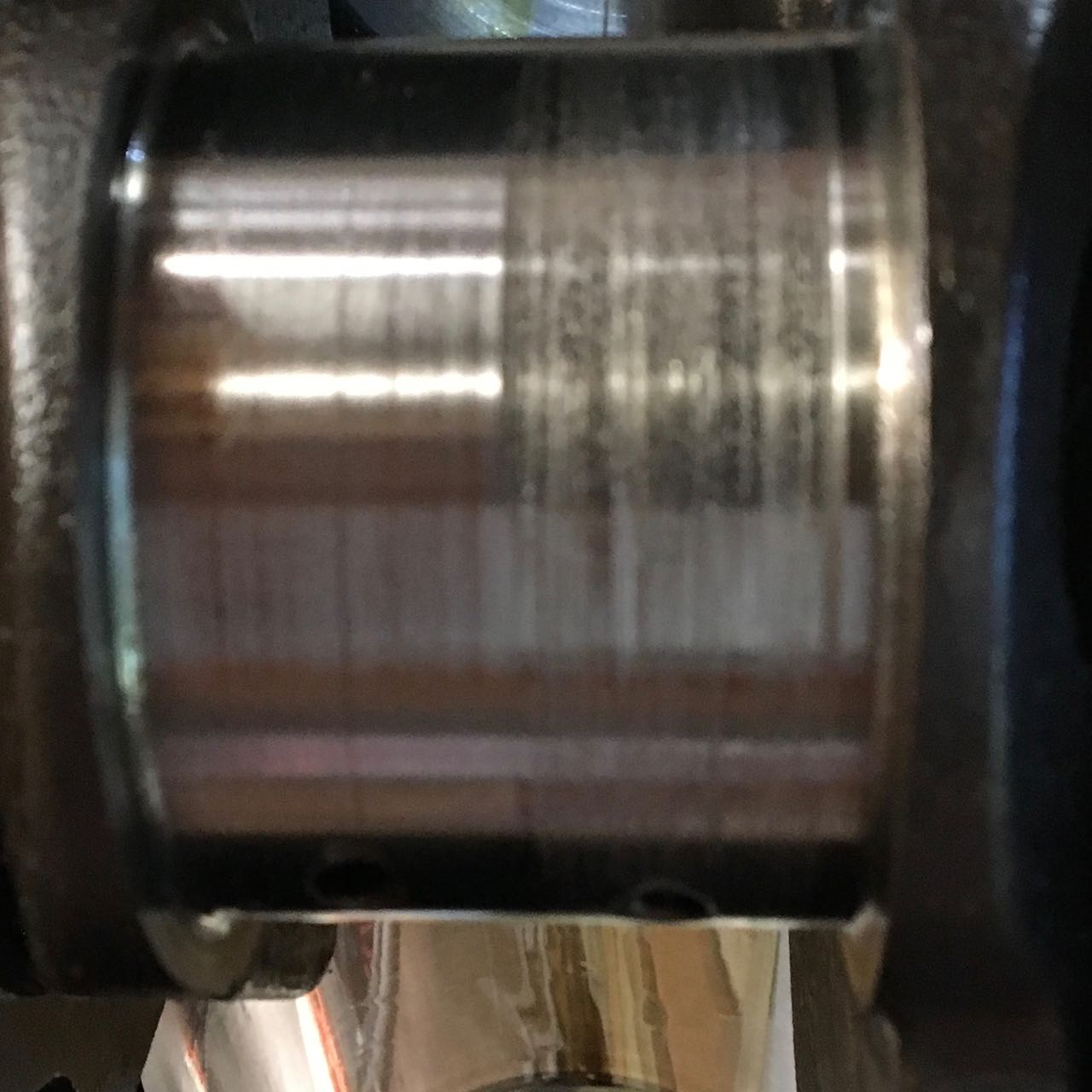

It began to knock and the oil filter is full of copper (or bronze) and some much smaller magnetic particles. I have not gotten into the engine yet, but I’m guessing the crank is going to be scrap along with probably the rod.

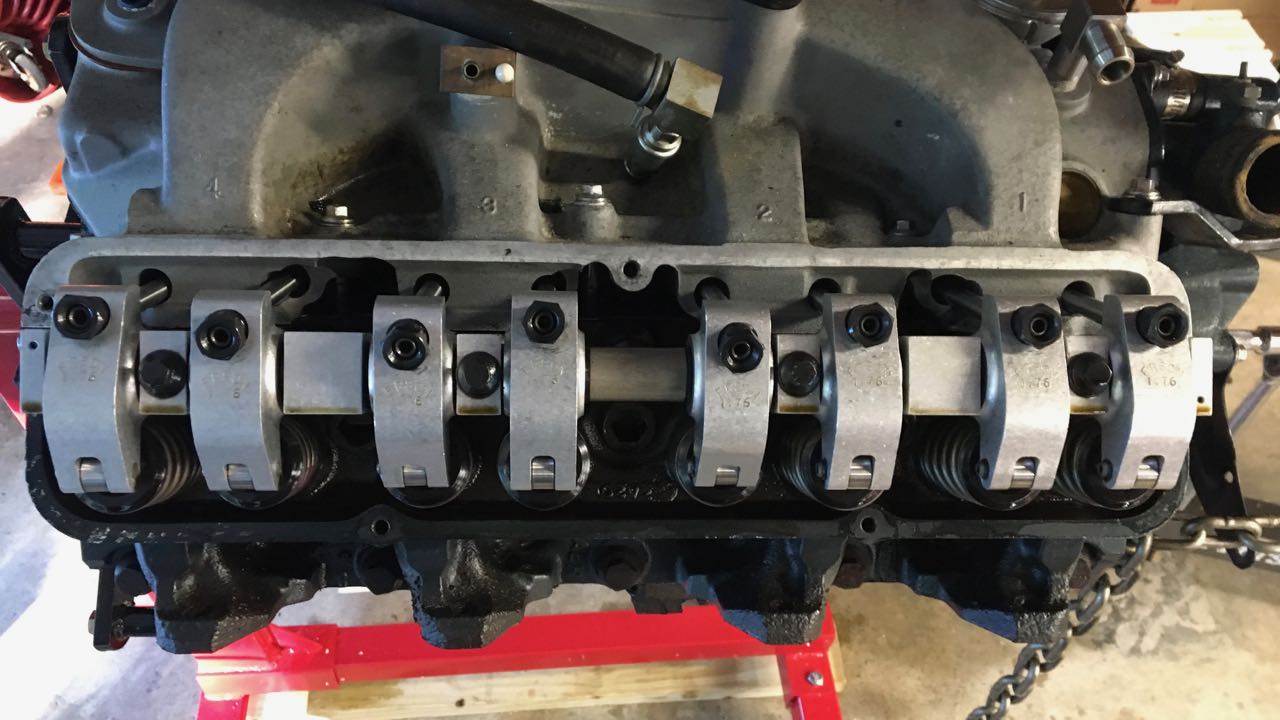

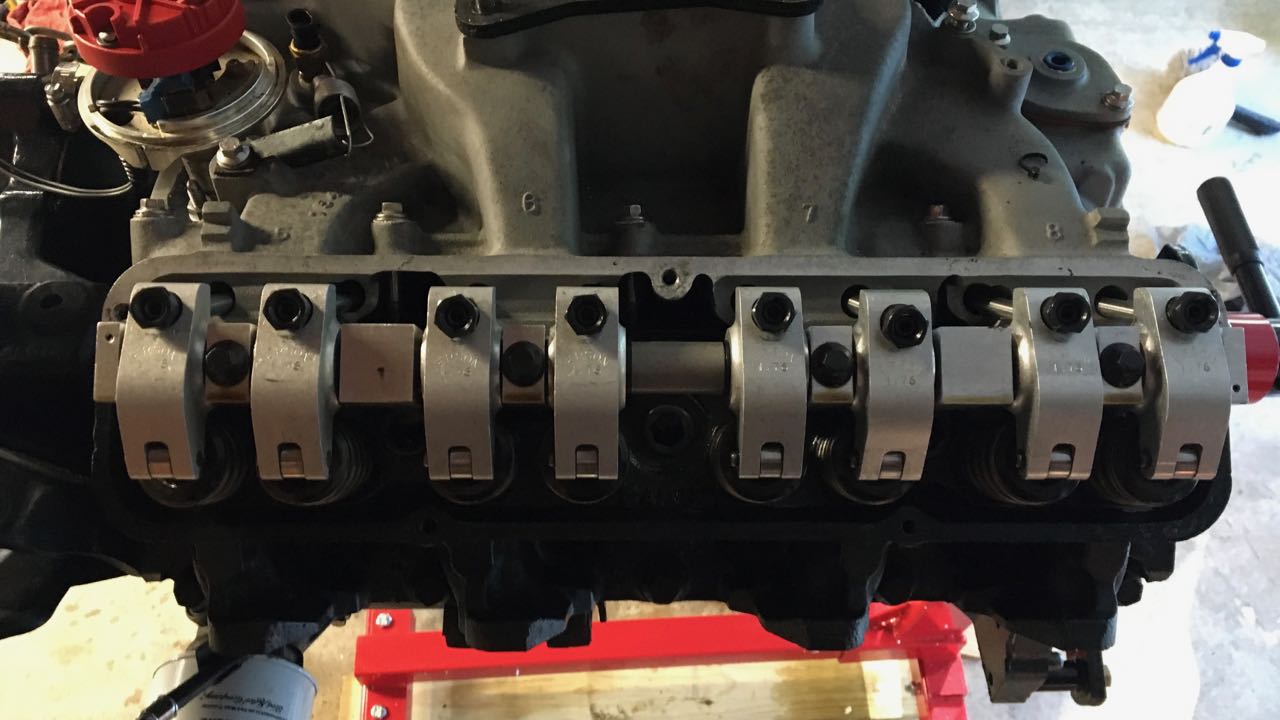

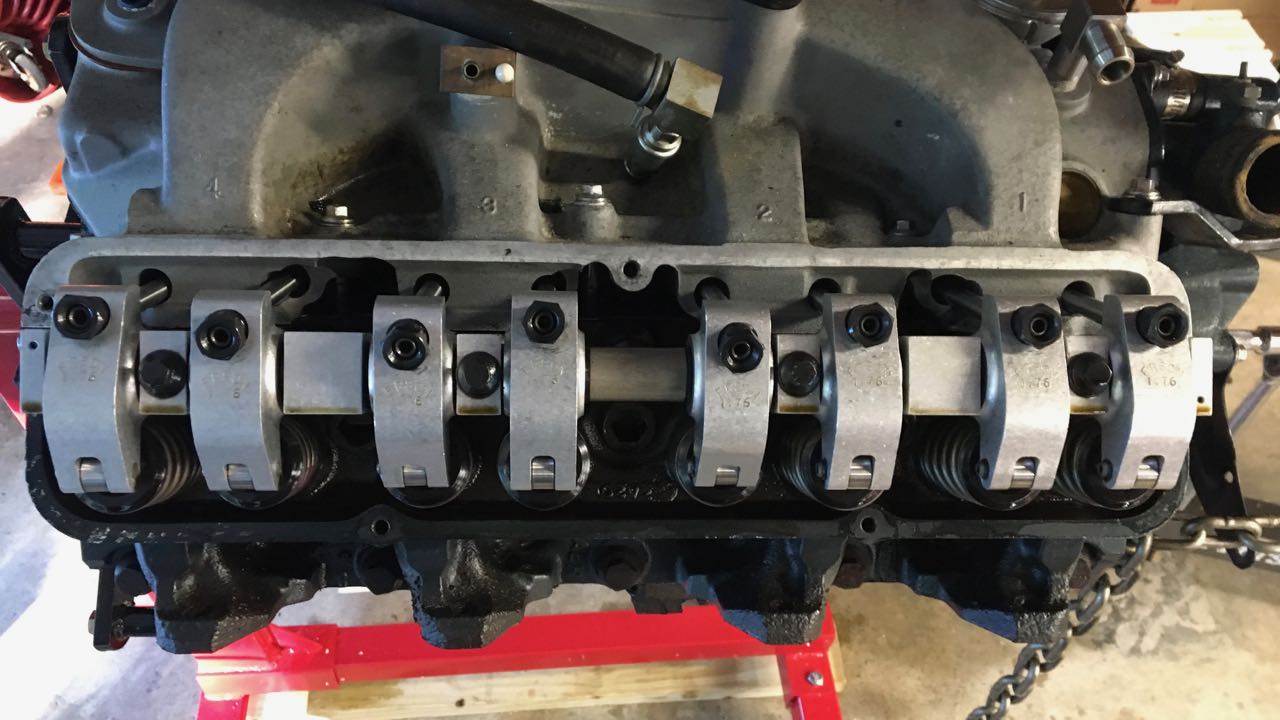

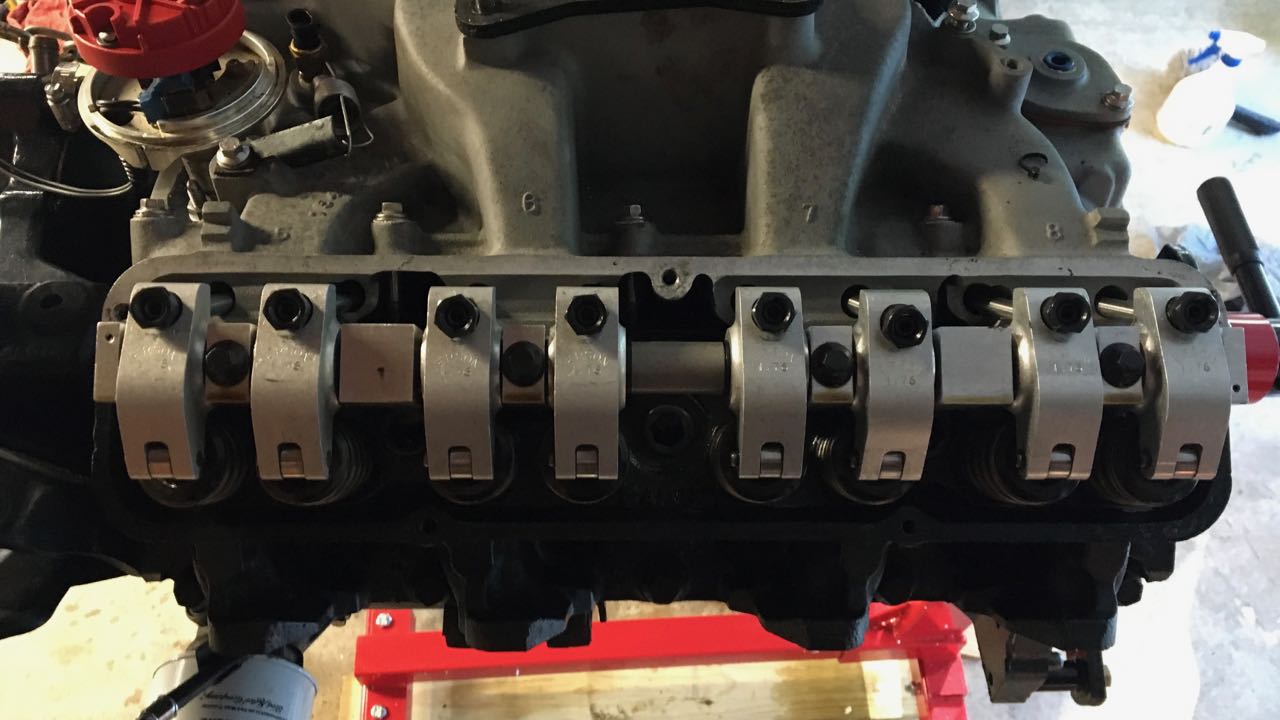

It is a .30 over 390, has a Crower street roller and HIPPO rollers and Erson Roller Rockers

My questions are two fold:

1) If the crank is bad - I will likely just do a stroker. Is there any reason to chose something other that a cast crank 4.250 rotating assembly for a street application? I don’t see it making over 450HP... though it spins pretty hard to 6500 or so RPM.

2) Any tips for cleaning the parts, particularly the roller rockers and lifters?

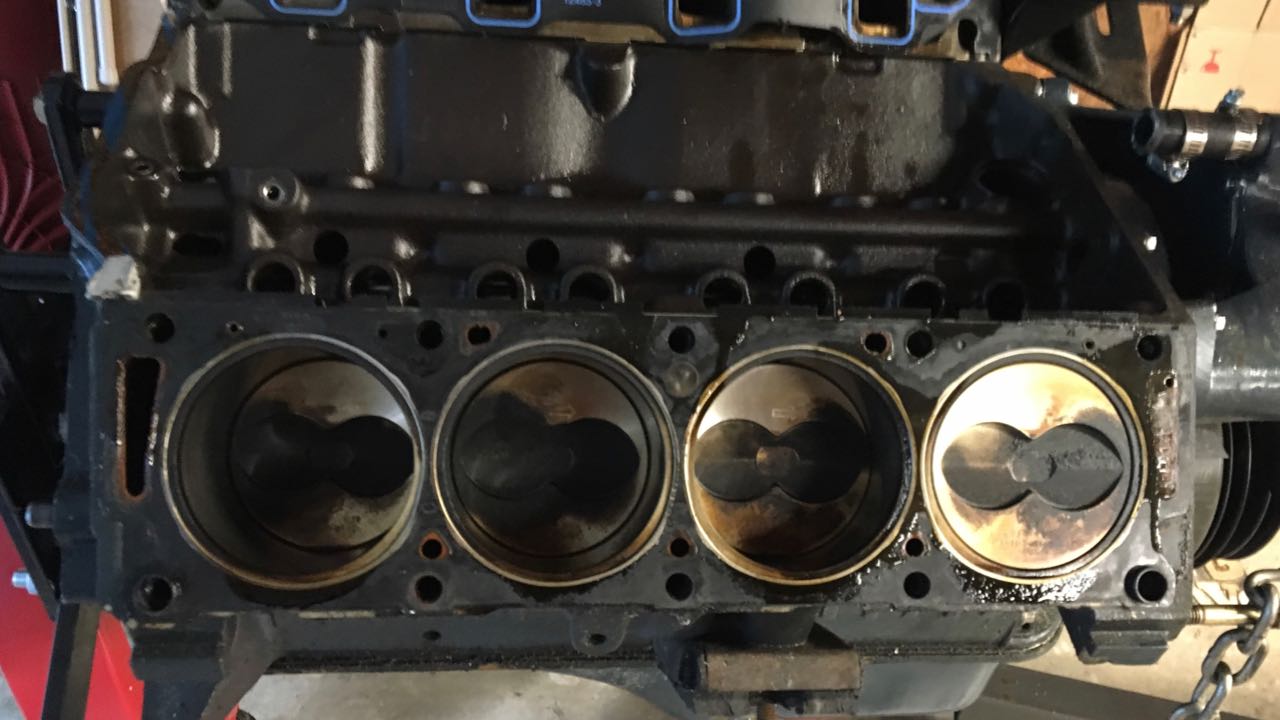

The block is the original 360 truck block (as near as I can tell) it was decked, align honed, bored with torque plates... assuming it isn’t damaged from this incident I’d like to reuse it at the current bore. It has about 3500 miles on it.

In fact I’m hoping to reuse everything that isn’t damaged.

It currently has L2291F30 at

zero (.004ish) deck and Victor head gaskets. I calculated the static compression ratio back then at 10.6:1. Once I get it all apart, re checking all measurements before buying parts is in order.

Mahle catalog shows a piston matching SCATS specs @ Compression height of 1.325 (incidentally they also show a 28cc piston that would get the compression down, but I don’t see an off the shelf kit using that piston.) Might definitely be worth a call to Barry or Brent to see what they can do.

The Cam is a Crower Part Number: 16462 Mechanical Roller (280R). INT/EXH - Dur @ .050” Lift:234°/244° RR:1.76/1.76Gross Lift:.580”/.582”

LSA:110° RPM:2500 to 6000 Redline:7500 (I really like this cam, I hope it is OK and I can make it work)

It does have an adjustable timing set.

It is fuel injected with a Holley Terminator Stealth, MSD pro billet distributor if it matters. Has a FPP (Which I think is the same as Blue Thunder) single 4V CJ intake which is a poor match to the heads... and Hooker truck headers.

No real evidence of metal in the upper end

Some flakes of copper / bronze in valley

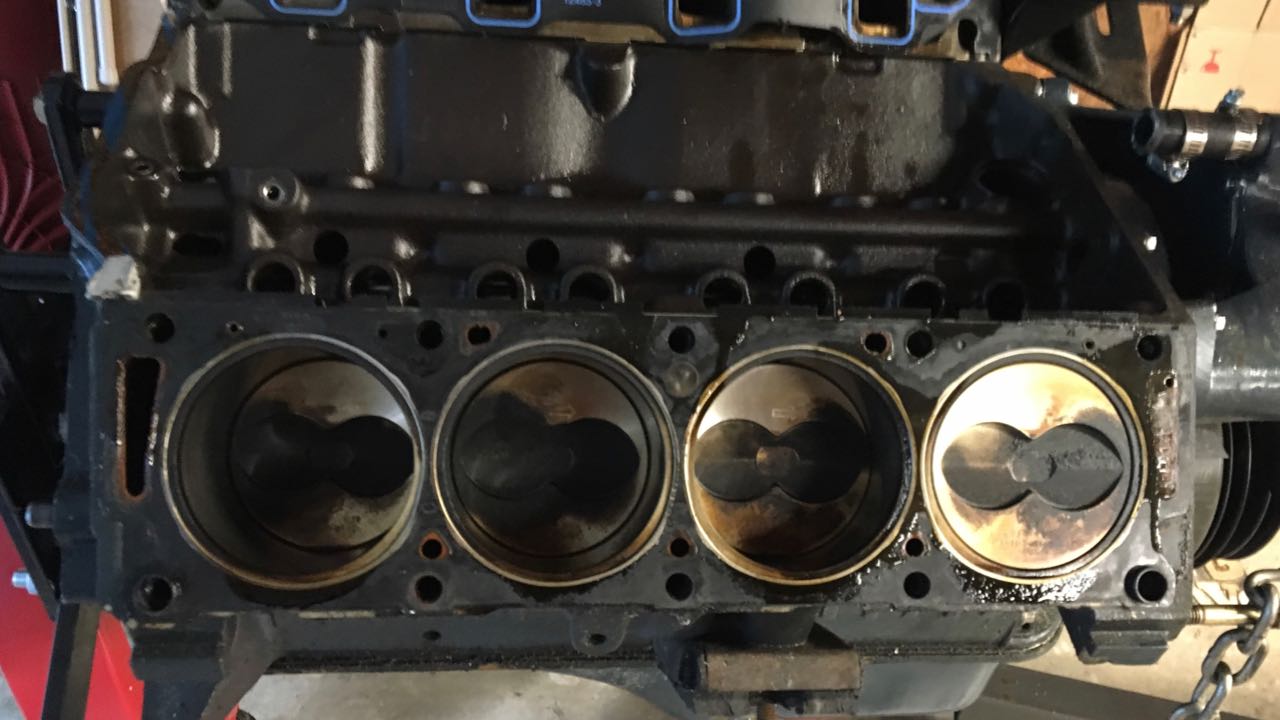

No evidence of issues on pistons

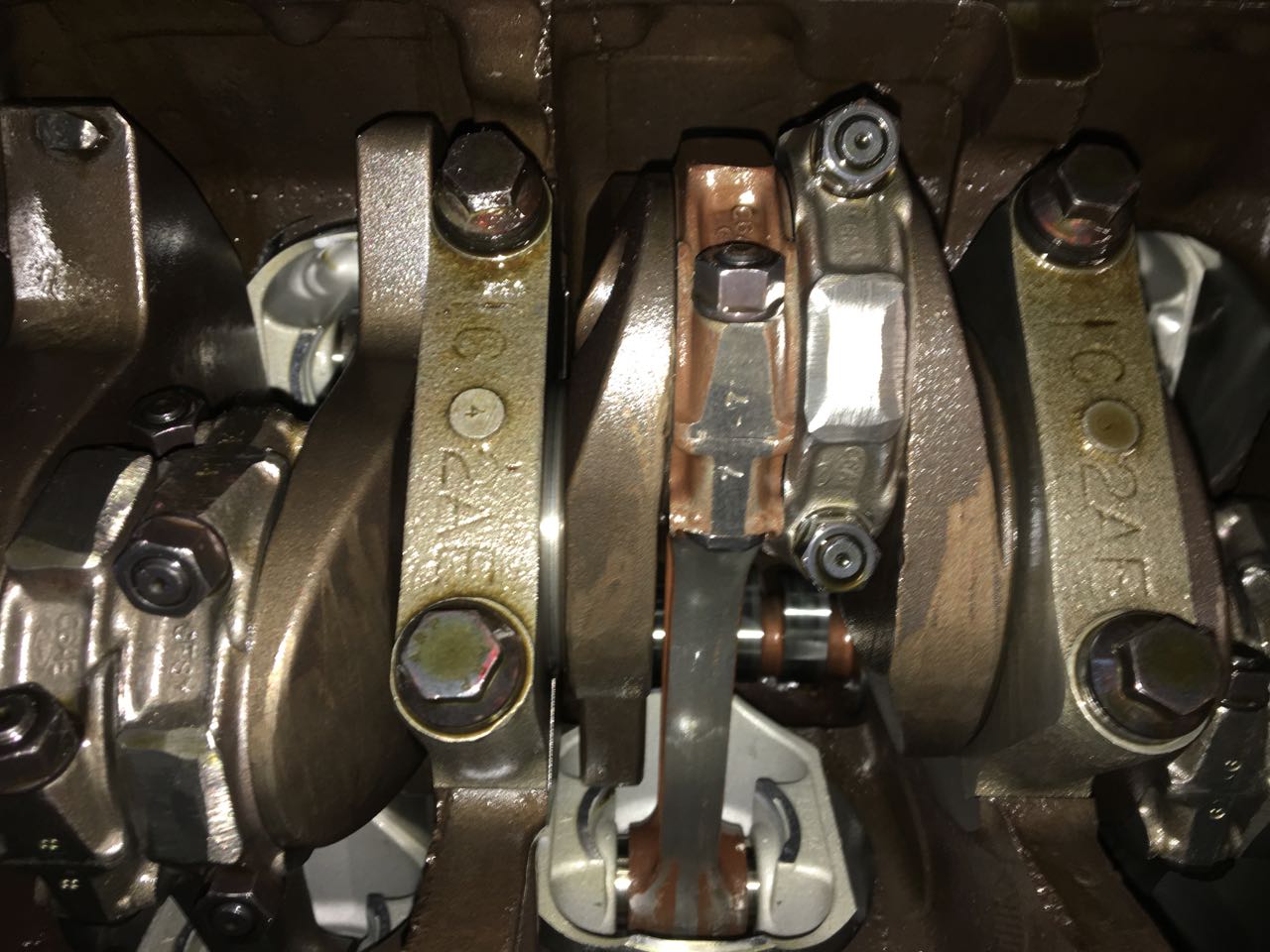

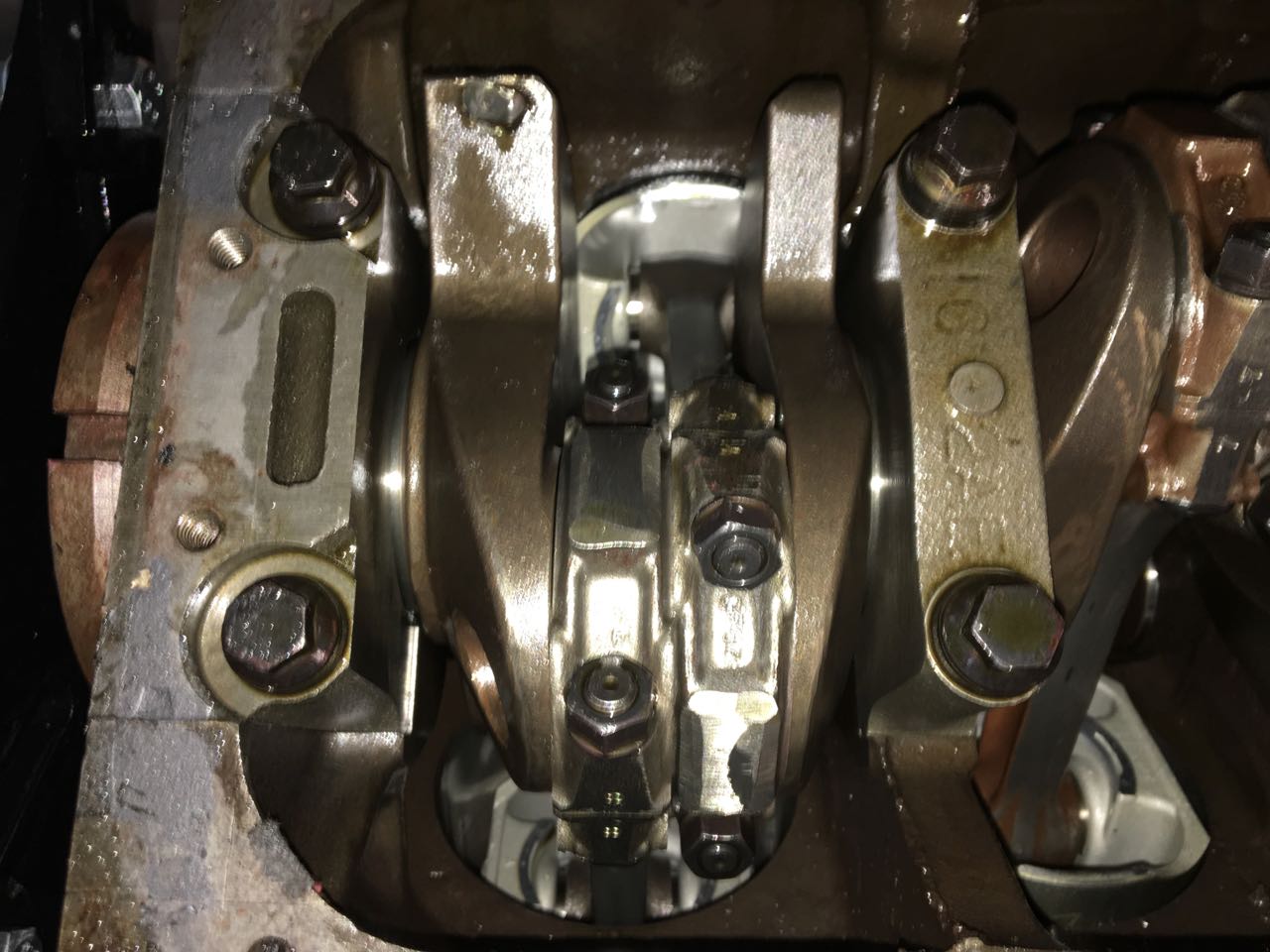

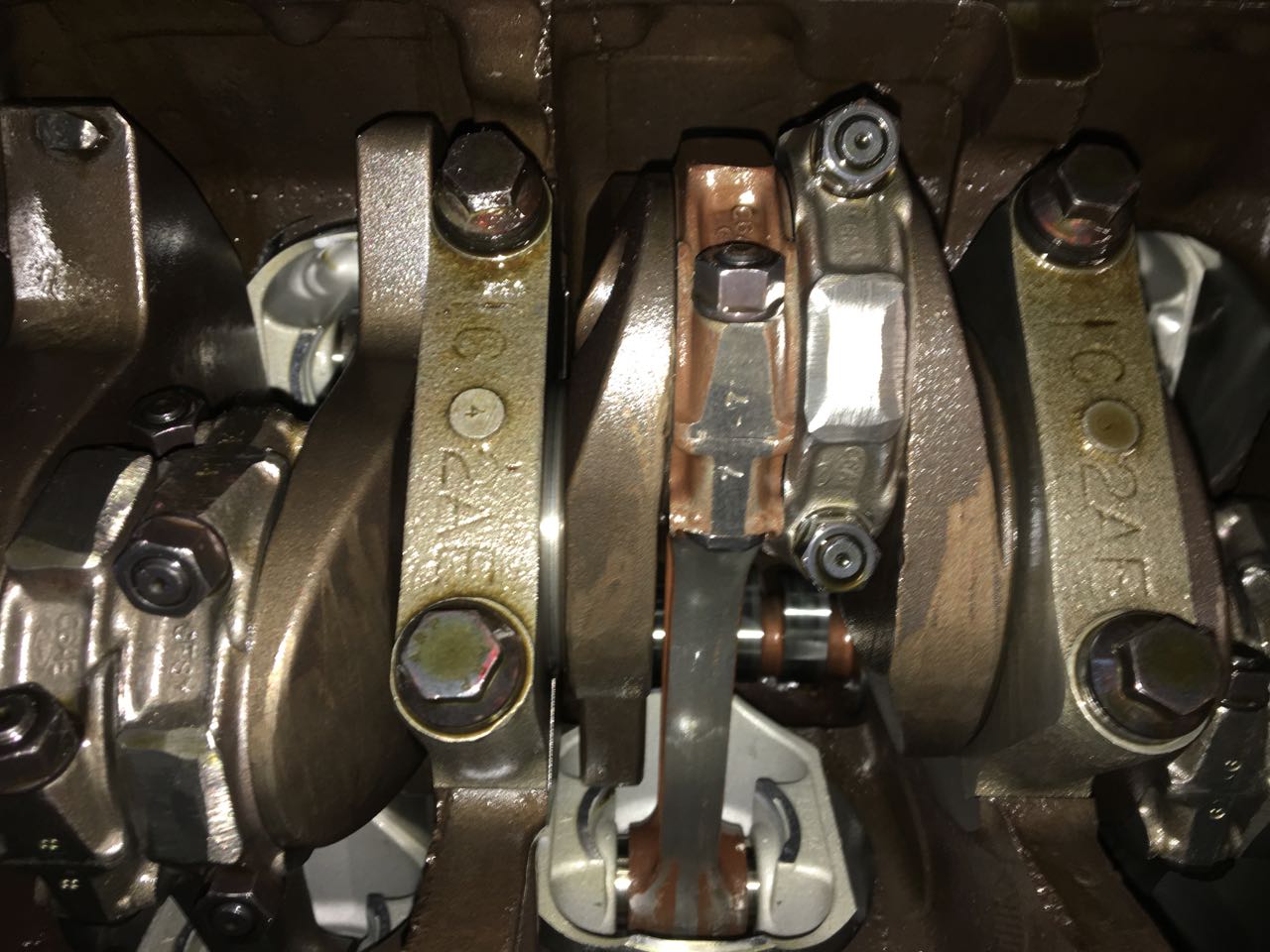

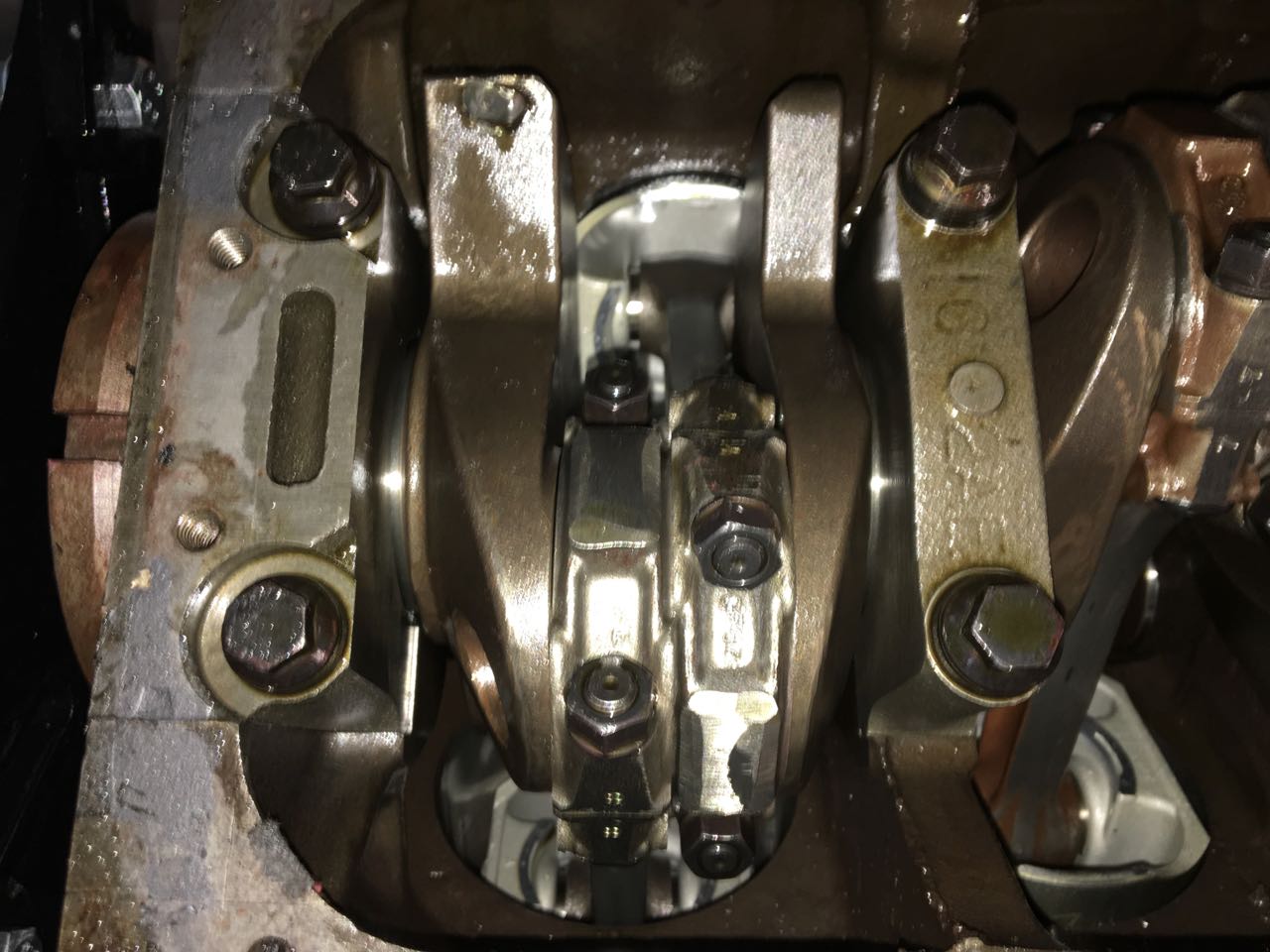

No obvious damage to rods or crank (no blue/black rods etc...)

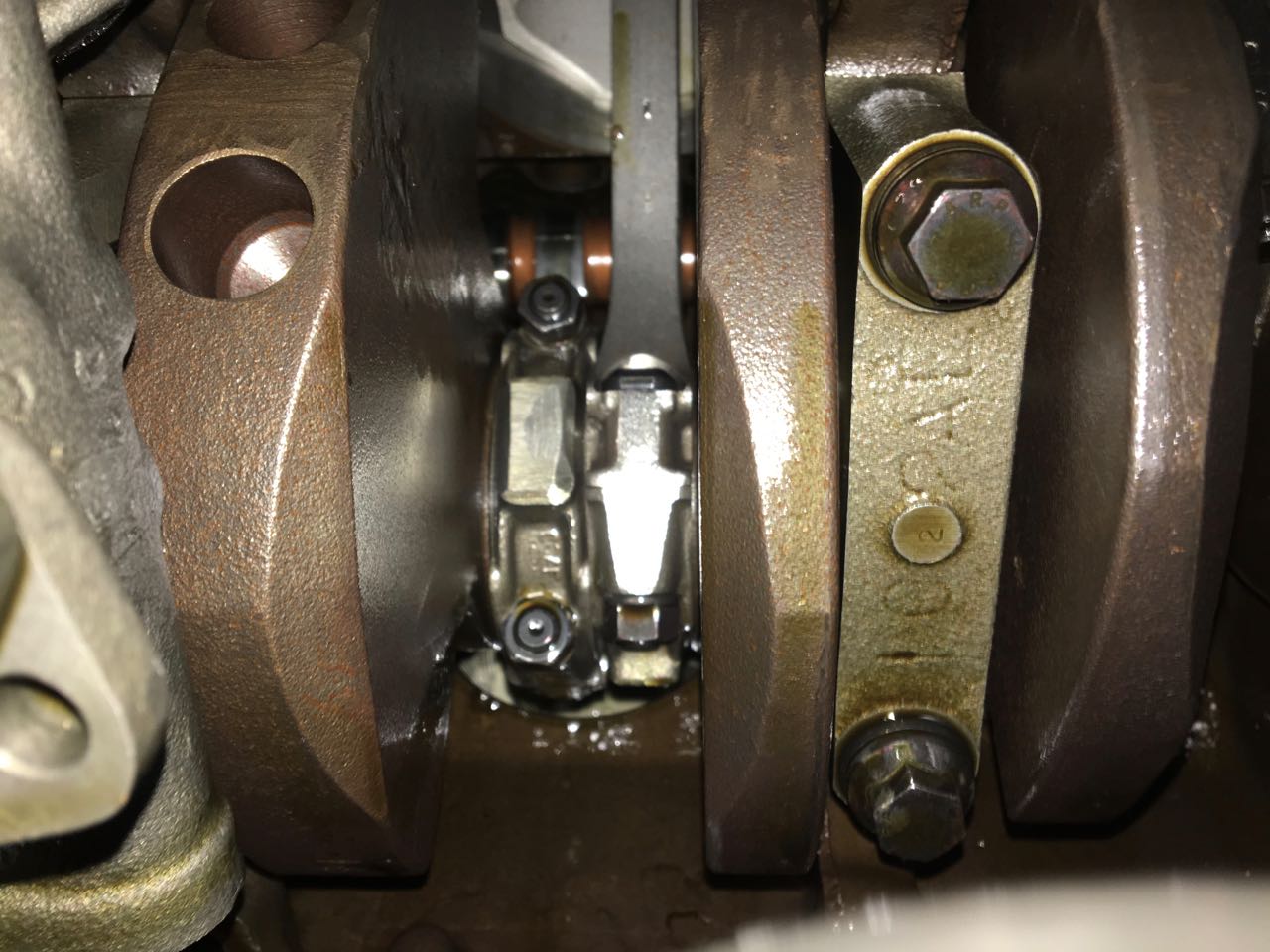

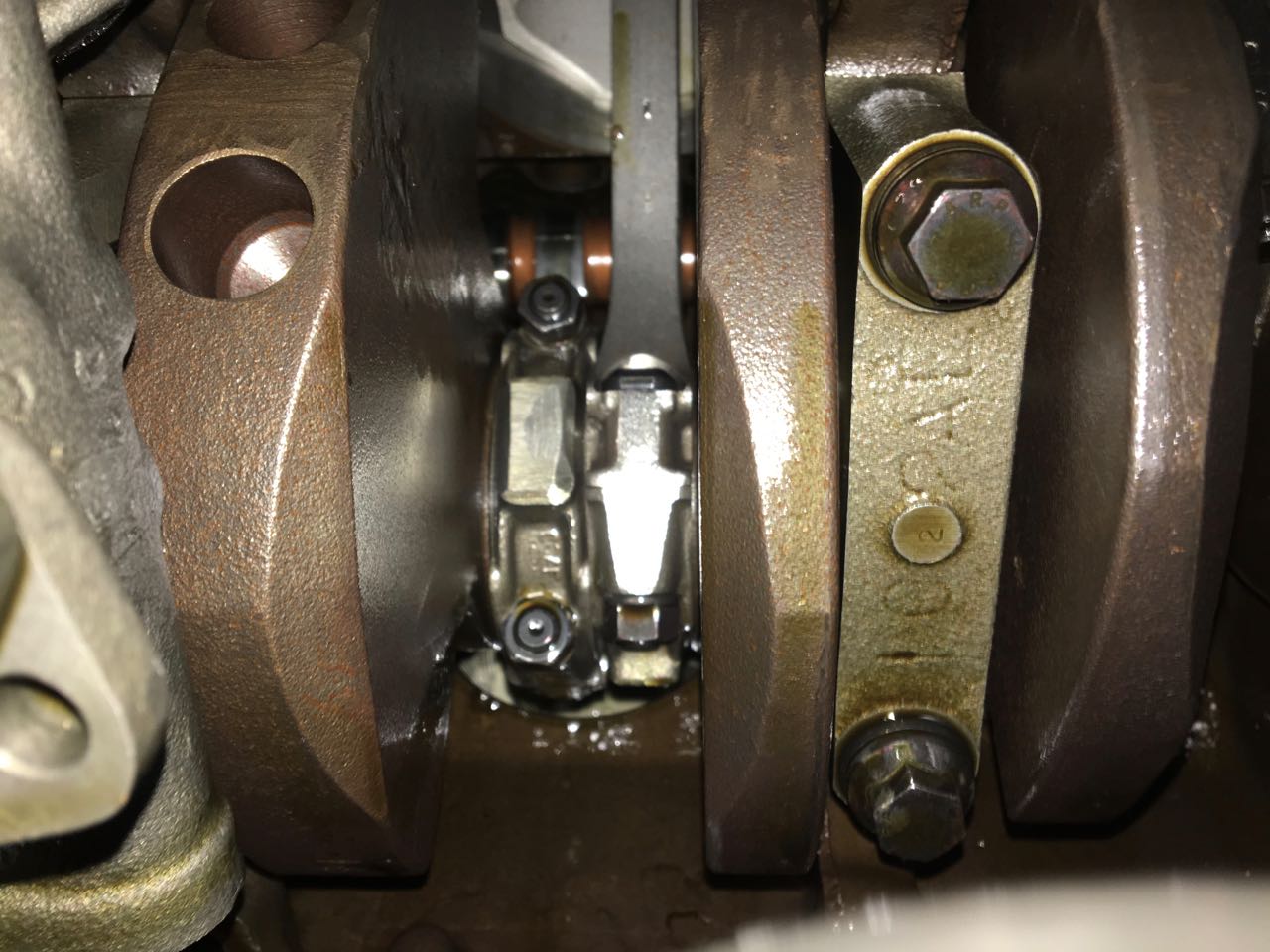

Don’t remember these marks but all rods seem to have them, so I am thinking its from balancing/machine shop fixtures...

5 is where it sounded like knock came from.

I did note that there seems to be excessive side clearances so checking that is on the list for tomorrow.

It seems to have zero end play, which I also don’t recall and will bear investigation...

Dist gear seems a little sharp so will clean and inspect that as well...

Well I would say the mystery about what is wrong is solved. This is number 7.

Now the question is why?

It still doesn’t have any end play, but the thrust bearing looks ok.

This was one of the copper colored rods, i asked about this back when I built it, but the consensus was some of them are just like that...

Other things I’m aware of are:

I had a converter incompatibility issue with a flex plate and it wiped the front pump in the trans, this was right after it was reinstalled, I was expecting to find issues with the trust bearing.

When the heads were ported epoxy was used to port match the CJ style intake to the MR style heads, last time I had the intake off one was found to be MIA (wish I recalled which CYL, probably should have written that down.)

I think my tolerance for trying to rebuild it as a 390 is badly waining... guess I need to get some more measuring done...