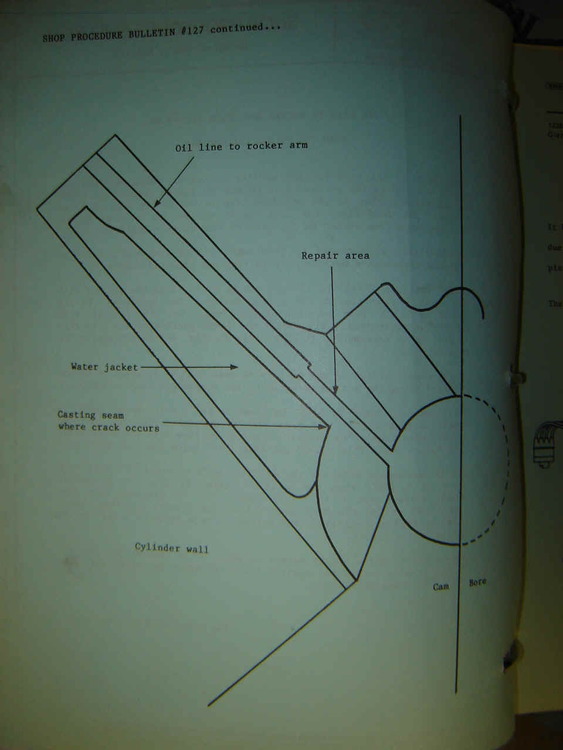

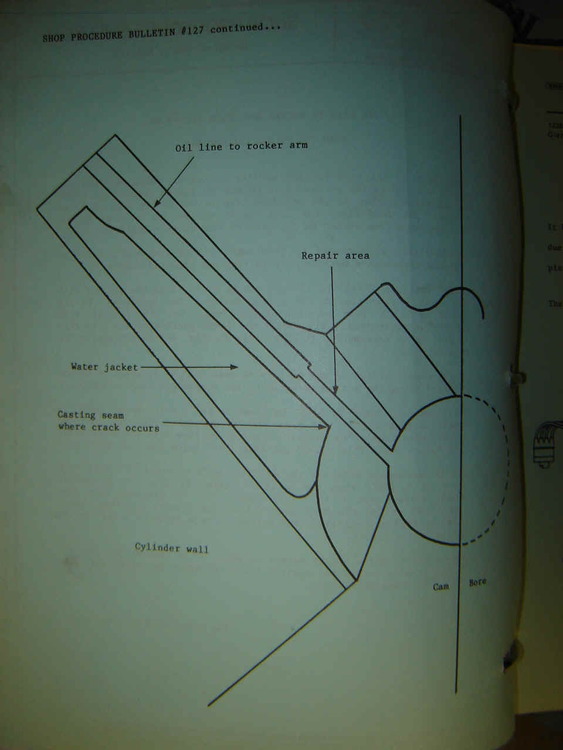

I have sleeved that passage on a couple of FE's. It was a common enough problem that some rebuilders in the 70's did it to everyone of them. I used a long drill bit and followed with a precision reamer, then a light press .001" interference with a Mickey Thompson Chevy chrome moly pushrod, using "wicking" loctite afterwards. The production engines that I saw looked done like a simple piece of 3/16" brake line.

With a reverse rotation engine, oil holes at 6:00 certainly works fine, I have never seen a problem with that. And Brent is correct about the cam bearing oil clearance, it is a good thing to know. Cam bearings are softer and more forgiving than rods or mains using a much thicker layer of Babbitt, about as close to an old fashion "poured" and "fitted" bearing as we ever see today.

AERA bulletin on the "oil in water" problem;