It was a busy, busy, busy week this week, mostly because my wife was out of town for much of the week at a conference in Denver. As a result, I was Mr. Mom even more than I usually am, spending a good chunk of most evenings getting my kids to Boy Scouts, softball, basketball practice, plus a little community service at the local food shelf. Nevertheless, I snuck in some work on the intake manifold when I could, and finally hit a fairly big milestone today when I got started on the welding.

I had been planning a book release party when my books first came back from the printer at the end of January, which I'd had to postpone because of the poor quality print job on the first copies of the book. Now that the reprints were here, I decided to have the party because a bunch of local guys had expressed an interest in buying a copy, and besides, I'm always up for a good motorhead party

The problem, as it always is, is that the shop was a disaster, and I needed to get it cleaned up before I had a bunch of people over. So, I was up late most evenings this week, cleaning in the shop, getting the tools organized, and clearing some space so people could stand around with their beers. Monday my new end mill came, so late on Monday night I got the end mill installed in the tool holder, and on Tuesday after I got home but before I took off to ferry the kids around to all their destinations I started up the sixth intake runner on the outside runner CNC program. As the week progressed I continued to make progress cleaning the shop, and Thursday night I got runner number 7 cut on the CNC. Finally, Friday night arrived with no activities for the kids, and I got the last runner tube CNCd and more cleaning work done. But despite that, I still had a lot of work to do to get the shop ready for the party.

Saturday morning I dropped the kids off at their activities, and couldn't stay with them because I needed to get finished in the shop before the party started at 7:00 that evening. I was back picking up my son at local food shelf, where he was doing a community service volunteer project for the Scouts, at 12:30, and then back out again at 3:00 to pick my daughter up from her color guard practice. She's getting pretty good at twirling that flag without klonking herself on the head like she did at first LOL! By 5:30 I had the shop nearly done, and I took off with the kids again because they were staying with their Grandma on Saturday night. Got back at 6:15, and within moments some early guests arrived, so I was still putting stuff away and sweeping the floors while the guys were looking around. Shortly thereafter my pals JC and Royce B showed up and helped get the cleanup finished, just in time for the rest of the guys to start arriving.

The party was a great time. I hadn't seen a lot of the guys in a while, plus some people showed up who I hadn't seen in a long time, so it was really great to catch up. One friend of mine I hadn't seen since the early 1980s; he got wind of the party and showed up, and it was a blast talking to him. My friends JC and BradFORD gave me a life size poster of an SOHC engine to hang up in the shop; it may be the coolest poster I've ever seen. Here's a picture of it sitting in front of the CNC machine:

My friend Greg is working on a couple of SOHC engines, and he acquired a sheet metal intake manifold for one of them that he is not planning on using in the near term. He brought it over so that when I get my 585" engine back on the dyno, I can test his intake. His manifold doesn't have tapered runners, which he thinks may cause a drop in performance, but it will be interesting to see how it compares to the Hilborn manifold I was running previously. He also brought over the Dominator carbs that go with the manifold. They sure look cool sitting on the engine:

Looking at that intake manifold, I was pretty impressed with the aluminum welding. The beads were nice and thin, and very regular. I was planning on starting the welding on my intake on Sunday, but figured I probably couldn't duplicate the workmanship on Greg's intake.

The party finally petered out around 1:30 AM. Sunday morning I was up around 9:00 and off to get the kids from Grandma's house. (Every time my wife leaves for a few days and I have to handle 100% of the kid's activities like this I develop a tremendous respect for single parents). Back at home, I spent a couple of hours cleaning up the shop after the party. This was noticeably easier than cleaning up the mess before the party (the mess that I'd made in the shop over the last few months LOL!) After lunch, I got to work on the intake manifold. I had talked during the party to a couple of people who were pretty experienced aluminum welders, and picked up a few more tips, so I was looking forward to getting going on the welding. After cleaning the burrs off all the runners, I washed them all in acetone, then took my stainless steel wire brush and cleaned up all the ends to remove the oxide that forms on aluminum after a day or so. Finally I re-cleaned all the runners in acetone, and set them aside.

I did the same thing to the plenum plates and the port plates on the intake, then assembled the runners and plates on the manifold jig. I cranked my powder coating oven up to 500 degrees and stuck the whole assembly in there. While it was heating up I made up a half dozen tungstens with the ball on the end for aluminum welding, and used some Scotchbrite to clean up the welding rods I was going to use (a tip I had picked up on Saturday night). My plan was to start with welding the runners to the bottom side of the plenum plates. I would have good access to the outside half of the runners with the manifold on the jig, but the inside would be tough, so I was going to weld the outside half, and then disassemble the manifold pieces so that I could weld the other half of the runners with the manifold apart.

Things didn't start off that well. When I pulled the jig and manifold out of the powder coating oven and tried to lift it, I realized that I was going to burn myself if I tried to lift it up onto the welding table. The whole thing must weigh about 100 pounds, and I needed to support it against my body when I carried it. It was too hot for that, and when I tried to throw a blanket over it to protect myself, it became difficult to manage. Plus I couldn't hold it too long even with the welding gloves; it was just too hot. So, I ended up dragging it out of the oven and onto the floor, and then flipping the jig into the position I needed, covering it up most of the way with the welding blanket to try to retain the heat, and welding it in that position.

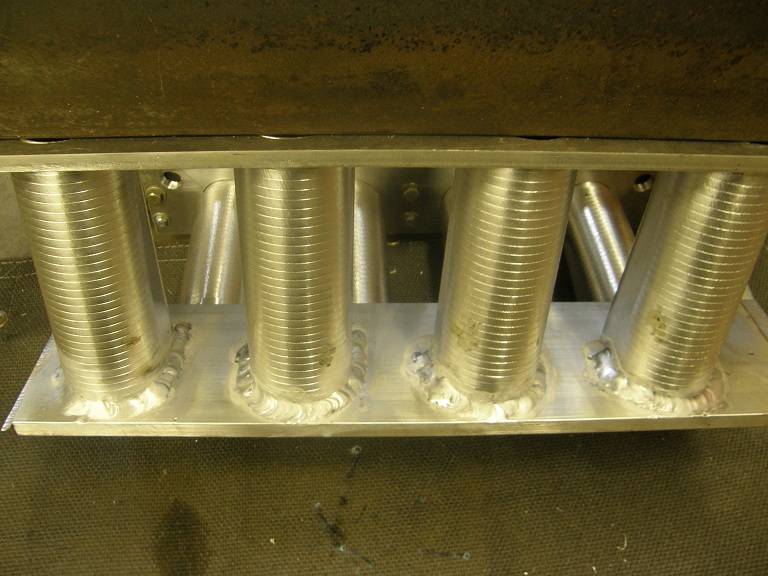

My knees were definitely rebelling at this idea, but it was better than not getting the welding done. Thankfully, with the pre-heat and all the cleaning I did on the materials, the puddle formed nicely right away, and the welding went pretty well. I was using my short-end torch so I could get in between the tubes fairly easily, but I still ended up dipping the tungsten in the puddle several times as I welded the first side of the intake. Every time I did that I just changed out to a new tungsten and kept going. I ended up having to weld both right and left handed to get to both sides of the tubes, and left handing the torch is a challenge for me, but in the end the first side came out pretty well. Here's a photo of the welding on the plenum plates and the runners:

After finishing that side I put the manifold and jig back in the oven, and spent the next few minutes reballing the tungstens that I'd dipped in the puddle, and scotchbriting more welding rods. I was using 4043 rod, and I'd used 3/16" rod on the first side, but I went through quite a bit of it, so I changed to 1/8" rod for the second side. After dragging the manifold and jig out of the oven again, I flipped it around to do the other side. This side went even better than the first, and I only screwed up the tungsten once while welding this side.

By now it was dinner time, so I went in to spend some time with the kids and let the manifold cool down a little. An hour later I went back to the shop, and took the now cool manifold back apart, to set up the runners for welding the rest of the way. Here's the runners and plates, disassembled on the bench:

I was going to get started finishing the welding on these, but I had more books to send out, so I reluctantly called it quits on the welding for the day. Nevertheless, I was very pleased with how the welding went, and I'm confident that I'll get the basic manifold shape welded up during the evenings this coming week. Next weekend I hope to get some more of the parts required for the intake CNC machined and welded together, so that next weekend it starts to look like a real intake. I'll post another report next Sunday night.