After a bunch of life happenings, I'm back. The scope of the project will have to downsize, so for now I will have to settle for heads, intake and headers. I can squeeze another year out of the 390 short block.

A few months ago I removed some broken bolts from the upper exhaust flanges. A few of the holes we're really ugly. Bolts rattled in the remaining threads. 2 of the holes had been drilled by the previous owner(s) and tapped 1/4" off center. The remaining pieces of broken bolts were left in and tapped.

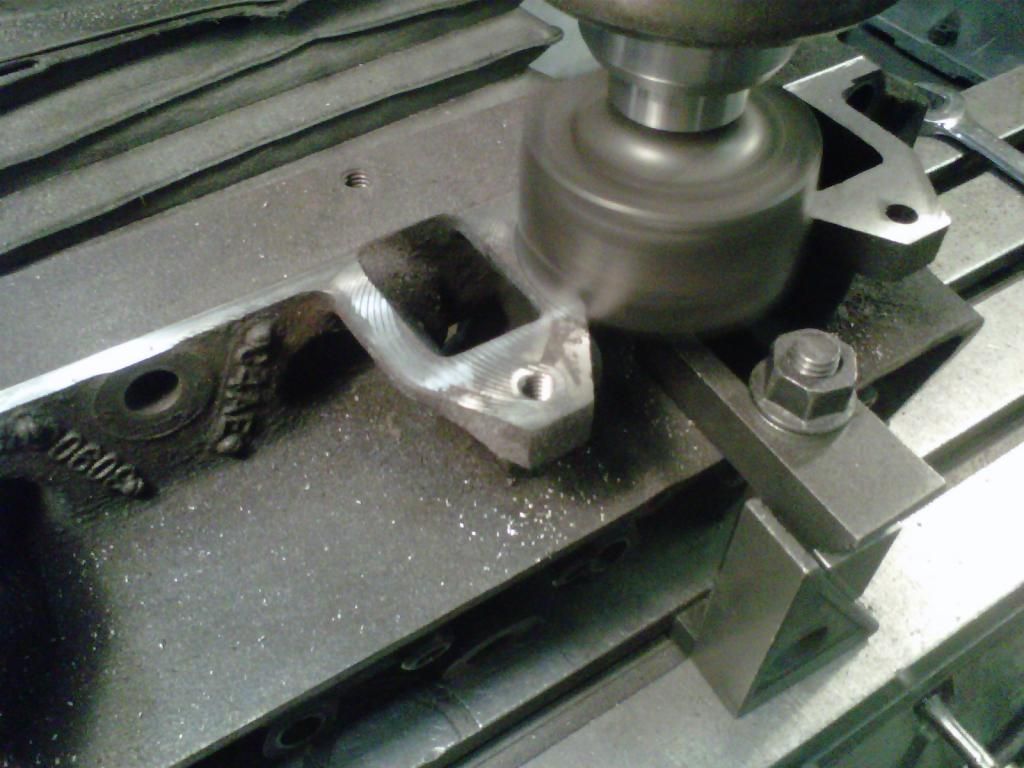

What a mess! So I made some threaded sleeves with 9/16-12 threads on the O.D. and tapped 3/8-16. The off center holes were plunged thru with a end mill and tapped 9/16-12. Now the holes are back on center!

I dimpled the threads with a center punch for an interference fit and installed the sleeves with a bolt and a jam nut, leaving a 1/16 or so standing proud for milling.

I milled .020 off of the exhaust flanges and still had some ate up spots.

It would have taken .060 to make that flange pretty. Will use some high temp pooky on that one.

So the rest of the required parts are on the way. Got a smokin' deal on a set of Manley 427 exhaust valves on epay. I did some wishful messing out in the garage today. Tried the full size exhaust valves with a std bore 390 block.

1.75 no go! Going to have to be around CJ size. Maybe see what 1.66 looks like. On the intake side will see how 2.15 fits.