OK, we have a partial answer to the big question. First, here's a couple of photos of Rob's engine on the dyno, the second showing the dry sump tank in the foreground:

After getting the engine hooked up on the dyno, we started the engine mid afternoon. I had hooked up one of my spare pressure channels on the dyno to crankcase pressure, because we weren't sure how much vacuum the dry sump system would pull in the crankcase, and Rob didn't have a vacuum release valve on the engine, so we wanted to watch that to make sure that we didn't develop too much and affect the internal oiling in the engine. When the engine started the vacuum creeped up to about 8 inches at around 2000 RPM, which was fine. After the engine ran for just a couple of minutes though, the Crane distributor gave up, and the engine died and wouldn't restart. Fortunately the distributor in the 352 stock eliminator engine was the same type, so we just swapped that one in to keep going. But after the engine restarted, suddenly we had zero crankcase vacuum. First we thought that the pressure sensor channel on the dyno may have gone out, so we swapped to a different sensor, but still the same result. Then we hung an analog vacuum gauge on the crankcase vacuum fitting, and still no vacuum. Finally it dawned on us that the new distributor was not sealing properly to the manifold, and we had a big vacuum leak there. So, we pulled the distributor again, removed the rubber O-ring, and wrapped the groove in the distributor body with teflon tape to make it larger in diameter, then reinstalled the O-ring and the distributor. This made a minor improvement, and we were back to about 2" of vacuum, but nowhere near where we had started. Finally we took The Right Stuff and fed it into the groove between the distributor and manifold, making a mess but also hopefully a good seal. When we started the engine again we were back to the original vacuum level.

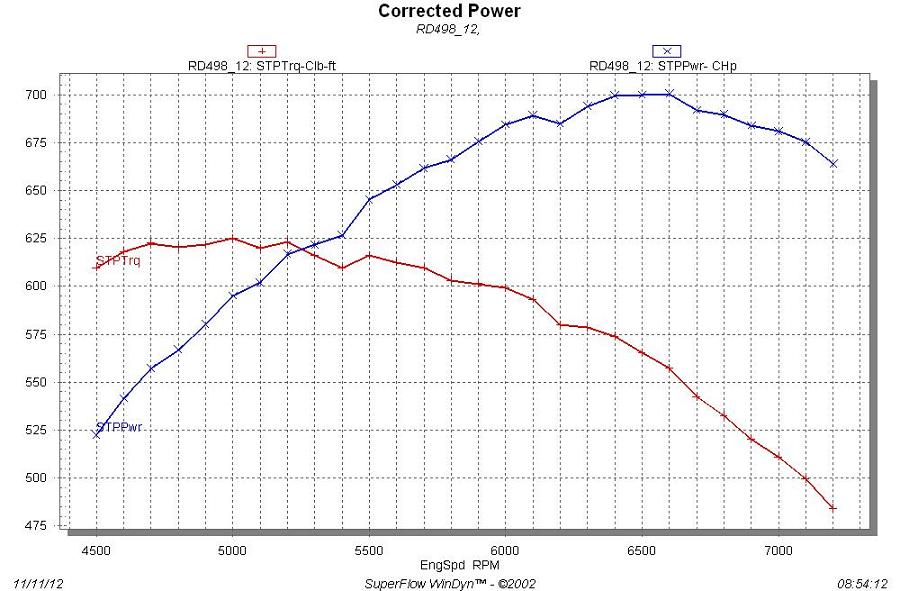

From there we started making some pulls on the engine, starting with 3000-4500 and working our way up to a 4500-6500 RPM pull. The engine made 685 horsepower right out of the box, with no jetting or timing adjustments, and didn't appear to be falling off at 6500, so we went to 7200. But we didn't see too much improvement there, and the engine was making its peak power right around 6500 RPM. The engine appeared to be running a bit lean on the top end, showing A/F numbers in the 13.5:1 range, so we decided to up the jetting in the carbs by a few steps. On the next pull we were down just a bit on average horsepower, so it seemed we had gone a little far with the jetting. With the dual quad carbs changing jets was a big ordeal of course, so rather than rejet at this point we decided to try timing next. We had been running 38 total with the distributor locked, so we increased the timing to 40 and made a pull. The engine really liked this change, picking up 3 average horsepower across the range and more at peak. The engine was breaking in nicely also, starting easily and picking up a little power, so we were running right around 696 horsepower pretty repeatably on the pulls.

Next we wanted to make a change to the collectors and see if that had an impact on the power. The dyno headers Blair brought are stepped headers, 1 7/8 to 2 to 2 1/8, with merge collectors. I had a set of merge collectors with a bigger choke point, so Rob and I installed those on the engine and made a pull. Results were nearly the same, but the bigger merge lost just a bit of average power across the range compared to the original collectors we had been using, so this didn't really help us.

By now we were getting close to the end of the day, and felt we'd wrung this engine out pretty well. We decided on one more set of changes: return to the original merge collectors, and take out some of the jet that we put in earlier in the day. I think we ended up with one jet higher than we had originally started with. This combination turned out to be the one the engine liked best, and we finally hit 700 horsepower with this combination.

So, after a day of tuning and tweaking our final dyno pull yielded exactly 700 horsepower at 6600 RPM, and 625 lb-ft of torque at 5000 RPM. Here is a plot of the data:

Today we'll be swapping to the single 4 intake and trying a couple of different carburetors on the engine. Rob prefers to run the single four intake in the car, so we'll be trying hard to optimize this combination also. I'll try to post the results late tonight - Jay