Summary:

- Still no dyno data, working through some casting issues on the cylinder heads

- Have cast the first couple prototype heads with the stock exhaust port location

- Modifications to the raised exhaust port head yielded a big improvement in flow, and the stock exhaust port head exceeded my flow expectations

- Next round of castings is due in January, hopefully all foundry issues will be solved by then and I can run the heads on the dyno.Sorry for the delay on an update for this project, I have been ridiculously busy with the project and getting ready for PRI next week, so I just haven't had a lot of time to post new information.

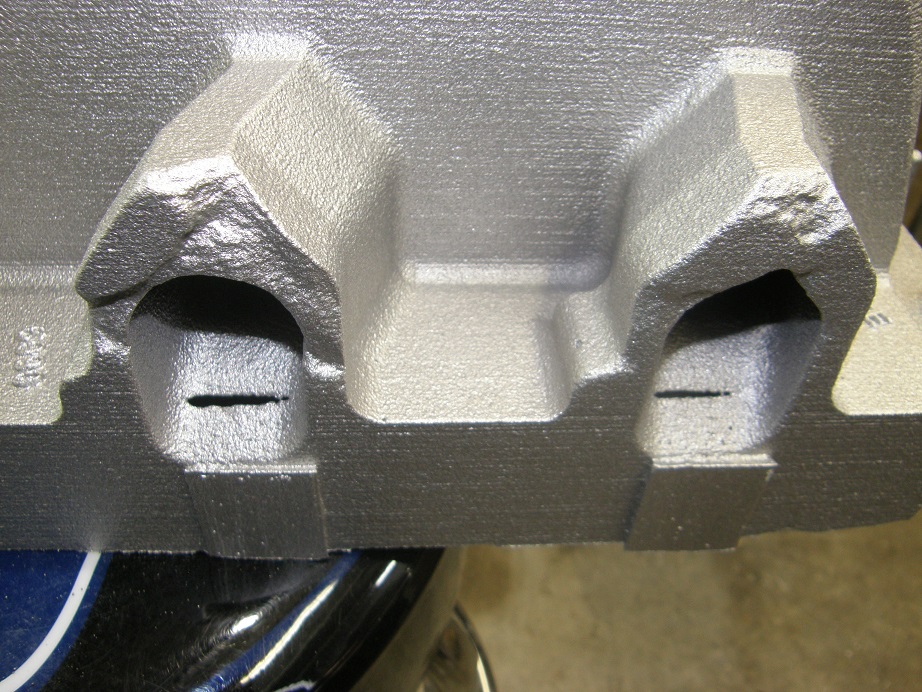

By this time I was hoping to have an engine running with my new heads on it, but various issues with casting the cylinder heads has caused some delays, and as a result I still don't have a set of heads that I am ready to run on an engine. Starting back in September, I had completed the design of the version of the heads with the stock exhaust port location, and got a couple more heads poured. However, the foundry had problems filling the mold, and the exhaust ports came out only partially formed. In addition, the water jacket core broke during the pouring operation, then floated up into contact with the exhaust port cores, resulting in holes in all the exhaust ports. See the photo:

Well, as a good friend of mine is fond of saying, if it was cheap and easy, everybody would do it.

It was back to the drawing board on the stock exhaust design, to try to resolve the water jacket issue. Also, the foundry had some thoughts about filling the mold, and was going to make a modification to their pouring procedure to try to addess that issue. After a month of work, I had more sand delivered to the foundry. The sand is shipped from the 3D print place, and up to this point there had been no issues with that, but this time the sand arrived with all the cores broken. Crap, another delay.

I had more cores printed, and actually went to the core manufacturer and picked up the cores myself, to make sure that they didn't get damaged in transit. This time the cores made it up to the foundry intact, and we poured again. The foundry tried pouring at a higher temperature, and we poured both the SE (stock exhaust) and RE (raised exhaust) versions. Unfortunately my changes to the water jacket design on the SE head was only partially successful, there were still a couple of spots where the water jacket core broke, and came up to breach the exhaust ports.

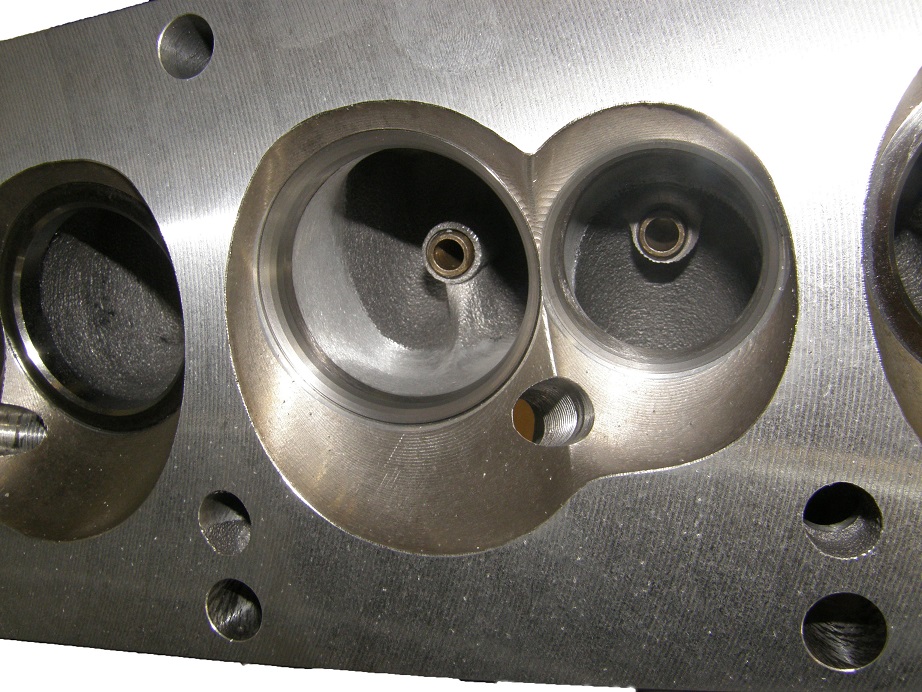

Nevertheless I took these castings back home to machine, because I hadn't yet machined one of the SE castings. The RE casting looked good, so I machined one of those first, then welded up the floors of the ports in the SE casting and machined that also. When I got finished I brought both heads in to the shop for seats, guides, and flow testing. But the first order of business was pressure checking the RE casting, and the very unfortunate result of pouring the aluminum at a higher temperature was some casting porosity. So, I had leaks in the cylinder head, which was a big disappointment; I hadn't had that with the first set I did last March. Somehow we are going to have to modify the gating and sprues of the casting mold to allow us to pour at the lower temperature, while ensuring complete filling of the mold.

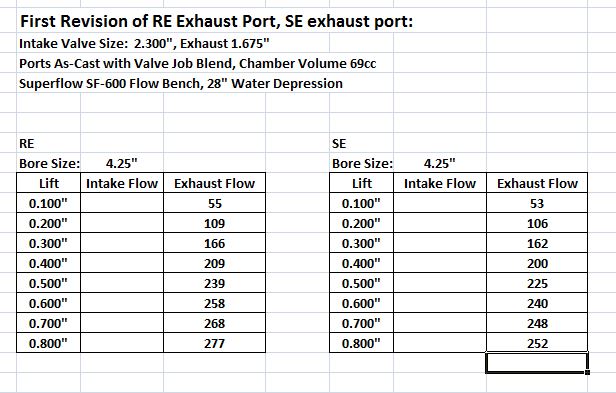

After the valve job, we did a flow test on the exhaust ports of both the SE and RE heads, and for a change this was a very pleasant surprise. The RE head picked up significantly, from a peak of 234 cfm at 0.800" lift, all the way up to 277 cfm! Now that port is flowing like I was expecting it to. The changes in the port design were driven primarily by the work of Joe Craine on a section of the head that I sent to him last summer, and also by my porting guy Bryan at R&R performance.

I wasn't really expecting a lot out of the SE head, but this was a pleasant surprise also. The flow from the SE head peaked at 252 cfm. This is almost as good as my CNC ported Blue Thunder medium riser heads, and of course those have a raised exhaust port. The flow data from both heads was obtained with just a good valve job, and blending of the bowl under the seat. No porting work was done. The flow test results are below:

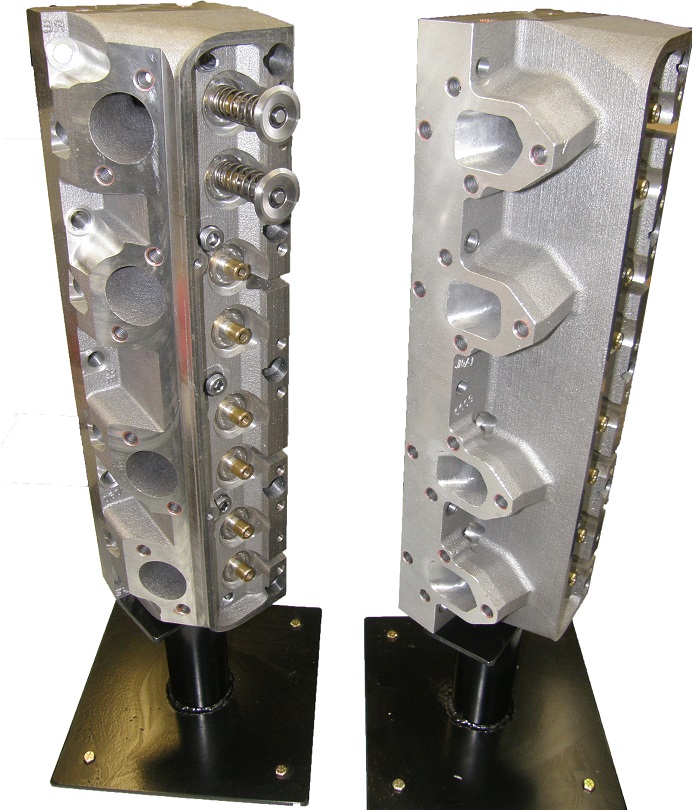

The foundry wanted to try one other test run of the heads, changing the pour parameters somewhat, so in the middle of November I had some more sand printed up, shipped to the foundry (no damage this time), and they poured one more SE and one more RE head. This time the RE head looked much better, but there was still one small leak in one of the spark plug holes in the pressure test, and the SE head still broke the water jacket core under the exhaust ports. Nevertheless I machined both of those heads, and since they are the most recent ones I will be displaying them at PRI next week.

After working with the foundry guys for the last couple of weeks, and also the pattern maker, we have a new plan going forward that we think will solve the problems I've seen this fall. I'm planning to pour another pair of heads in January, so we will see how it all works out. In the meantime, here are some pictures of the recent castings. In the first photo, you can see from looking at the roof of the ports that only one of the exhaust ports on the SE head is correctly formed; the foundry is still having trouble filling the mold:

The picture below shows what the whole cylinder head package will look like:

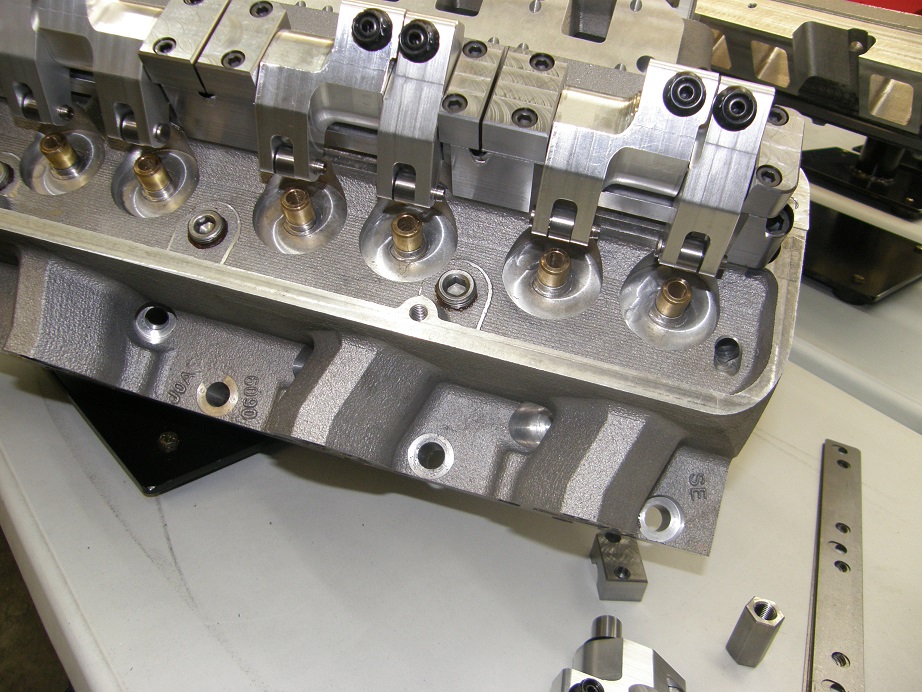

Here is a picture of the rocker arms. These are machined from 7075 billet aluminum. Also in the picture is one of the special head stud nuts that will be required with these heads. They have a different thread on the other side, for bolting to the steel bar that supports the rocker assembly (second picture). So, the rocker assembly bolts both into the cylinder head casting, and also into the head studs. Finally, you can see the long steel shims that will be provided with the heads to allow adjusting the height of the rockers, for optimizing rocker geometry:

Here's a picture of the SE head with the rocker assembly bolted on:

I make my apologies in advance for not having a lot of time to answer questions on this, I am completely buried in getting ready for PRI. If you happen to be attending the show, please stop by the FE Power booth and say hi; we are in booth 4353 in the main convention hall. Thanks, Jay