I'm going to try & cover this in a single message - sorry about the length...

Just got back in and unloaded from this year's EMC deal - ran on Friday. Short answer is that we finished "third", performed well, and got some positive attention for the FE faithful. Much longer answer to follow.

First to cover is the contest itself. Hot Rod is running EMC now, and they instituted some pretty dramatic changes. They have five classes - each unique and on a different day.

Day 1 was Mopar Hemi - they only had four entries - Bischoff's "new" one won by a lot.

Day 2 was spec small blocks, built out of the Edelbrock & Comp catalogs - Kaase won & Malik 2nd.

Day 3 was LS motors built "on site" - 3 entries, one ran w/o cooling, one won, and one caught fire.

Day 4 was "vintage" - flat out cool and creative - Kaase won this too, but creativity was awesome.

Day 5 was "big block", similar to older rules, and where I ran with the FE

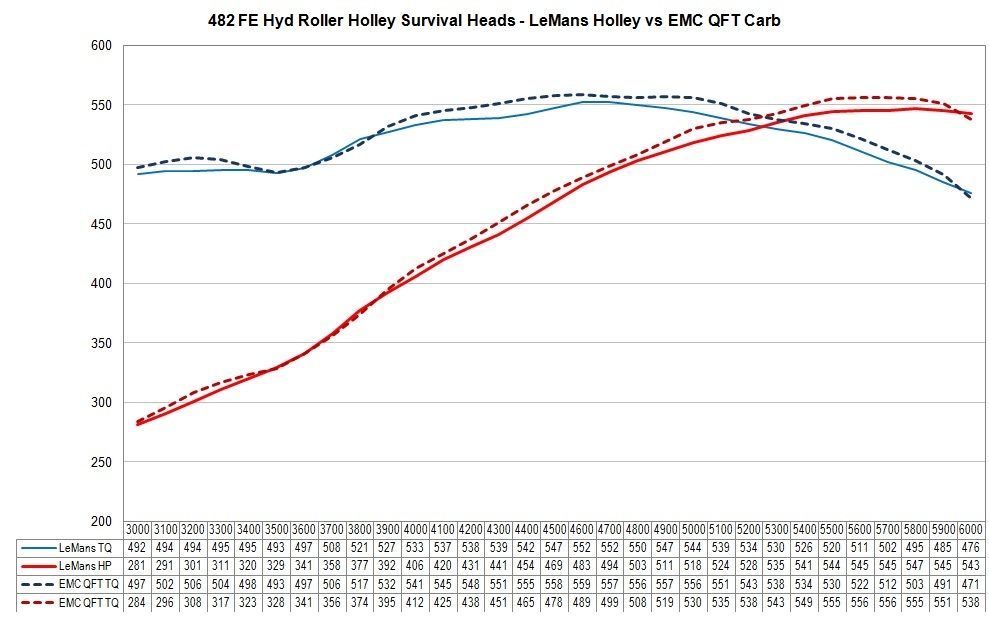

Scoring on day 5 was average power plus average torque over 3000-7000 RPM, divided by cubic inches

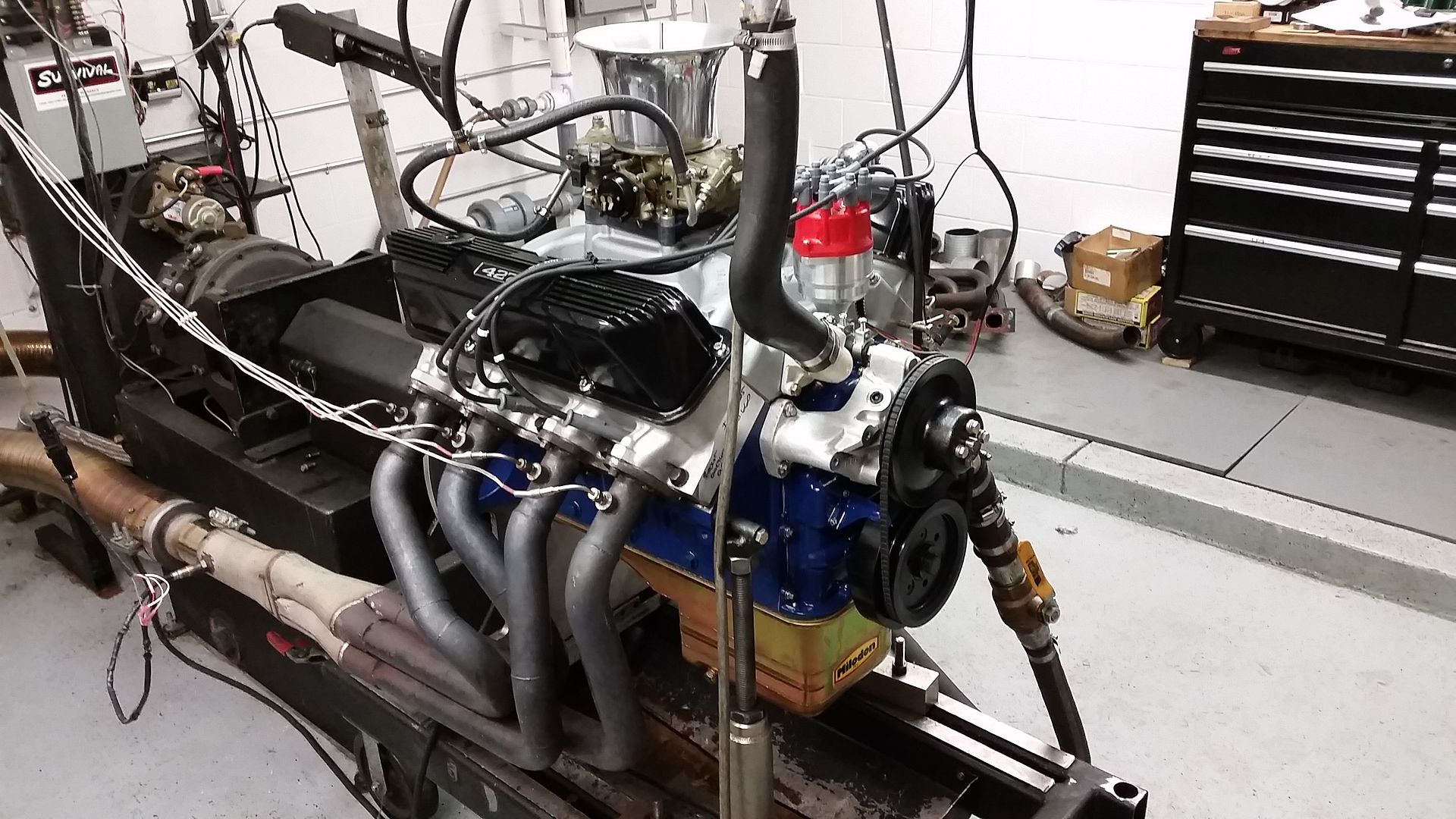

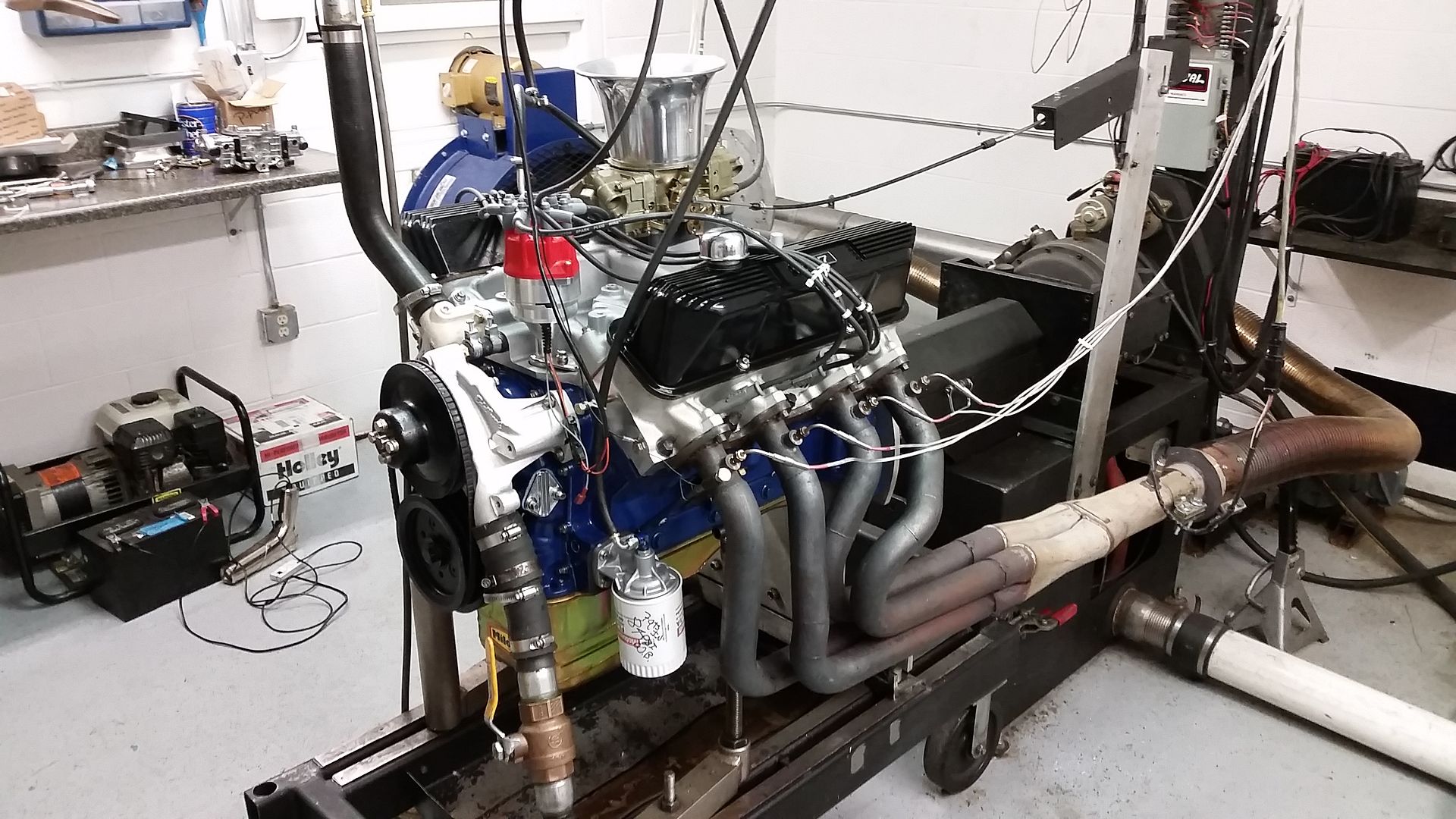

Next is the engine we built. They were really late getting the rules finalized and the entries approved. Meant we had a very short build window & used a lot of stuff we had "around". The vast majority of the build and assembly was handled by William Blair, my machinist at the shop. I've had significant "non-shop" stuff taking up a huge percentage of my time, and "Willie" stepped up to the challenge. This is really his engine with my parts selection help. Its a pretty standard 482 with a 4.25 bore and 4.25 stroke.

The block is probably the first Sideoiler Garage iron casting. It was a non-production test/design/development piece and was destined for the scrap pile. It is not a sellable part, but proved itself usable for this purpose. We stitched up some inspection holes and filled it with hard block up to the water pump & maybe a touch higher. Crank is an out of the box Scat forging, rods are out of the box Scat H beams with ARP2000 bolts. Heads are Survival CNC from last year's effort - we pulled them off my car and tuned them up with better springs, etc. Pistons are based on catalog Mahle parts with valve pockets reworked, gas ports added, and the rings back cut like crazy to reduce tension - compression came in at 11.37:1 against a rules limit of 11.5. Cam is a solid roller from Comp with 248/252@.050 duration, .794/.785 lift, on 104 LSA installed at 102. Rockers are T&D race with a 1.9 ratio. Intake is an Edelbrock Victor 4500 EFI initially ported by Joe Craine, and subsequently tweaked by John Marcella to accommodate a single blade throttle body. Oil pan is Ford truck circa 1970s. Used one of Jay's two piece timing covers and one of my adjustable timing sets as a proof of concept.

Dyno testing at home went well, with a total of about 54 pulls being made. I think I mentioned the dyno numbers previously. We tried 49 pulls on EFI getting to the best repeatable timing and fuel curves. I thought I had it pretty well sorted and stuck my old 4500 QFT carb (from the 2005 EMC) on it just to check. In the past I've always done this and the EFI always "won", but this time the carb did very well although extremely rich. A quick - and large - jet change brought it even closer, and another jet move brought it right up to the EFI scores, but with a better looking torque curve down low. The importance of that will be shown in a bit. As a last ditch effort I assembled another set of headers with larger primary tubes and some NASCAR collectors - they gained huge down low but fell off really badly from torque peak & beyond - lost a bunch of score, but something that will mandate future attention because it proves there is something to find in that exhaust. The dyno exhaust installation at the school where the contest is held is very different from mine, so tuning around it is a bit sketchy. I knew which exhaust to use (the original stuff) but was undecided on the carb vs EFI question - so I decided "not to decide" and brought both intending to start out with the carb and switch if time permitted.

Now to cover the event itself. We were the second engine up on Friday, They give you 35 minutes from first fire up to do as many pulls and changes as you want, taking the best three to average your score. Rolled it into the cell, hooked everything up and fired it on the carb with zero drama. A quick timing check (used the EFI box to control timing which simply wanted a flat 32 this year). We made four pulls with some simple fuel changes - it was leaner than at home - the different exhaust made for large changes in graph shape but no really big changes in score or peak numbers. We then went into a thrash and converted to EFI. That went surprisingly well and we got four more pulls in with very similar results to the home data - higher peak HP and lower torque & similar scores.

Most guys focus on the "Hollywood" numbers. Between home and contest we ended up with a best horsepower number of 738 with EFI at home, and a best torque number of 669 with a carb at the show. That 669 calculates to 1.387 torque per cube - inline with my best efforts and in line with expectations on a well developed engine. The peak horsepower observed at the contest was 728, the peak torque at home was 664. My dyno is within single digits of the one at UNOH.

Now for some graphs because this posting is not long enough yet.

First graph is an eye chart showing the eight contest pulls along with a couple of representative home pulls. Don't bother trying to read this one - just make note of the trends. At EMC we concentrate a lot on the bottom end because that's where all the variables are. As RPM climbs the graphs show a strong tendency to converge, meaning that power peaks are not as significant a score opportunity as the first 1000 RPM are. At the contest the dyno operator had a hard time "driving" the EFI combo and lugged it down to 2400 RPM a couple times - NOT his fault - its a real bitch to get a good pull started with a huge single blade throttle body - but those pulls really killed the bottom end scores as the engine struggled to recover.

Those with a number are contest pulls, those marked with a "s" are shop pulls at home

I'll use a fewer number of pulls in this chart to make it easier to read...

Next we can take a look at a couple home pulls. A bit easier to read, and illustrates the difference in curves between the EFI and carb even though the scores are similar.

The last chart shows a carb and EFI pull at the school. You can see that the trends are similar even though the curves are different.

Mr. Blair used my phone to take video through the dyno room door...

[img]http://youtu.be/P2jw7J1Rp-g" rel="nofollow">

https://youtu.be/P2jw7J1Rp-g</a>